Bilfinger helps PRTI to cut emissions in the cement industry

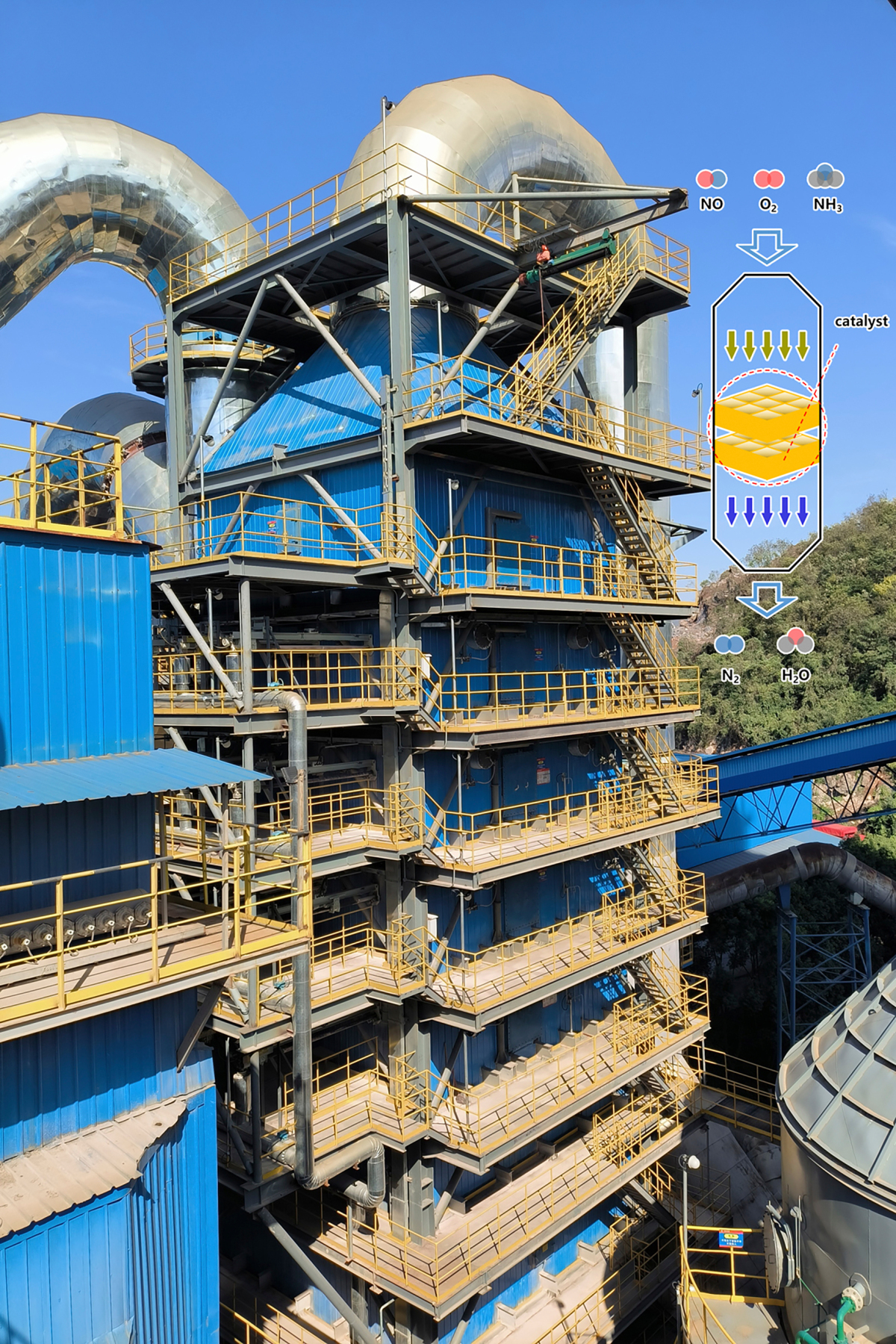

Cement manufacturers are facing the challenge of meeting increasingly strict emission standards while continuing the energy-intensive production of cement. Bilfinger is supporting the US-based tech firm PRTI in bringing a technology to Europe that can help cement companies reduce their emissions. Bilfinger Tebodin is the engineering partner for adapting PRTI’s technology so that it meets the strict European safety and environmental requirements.

PRTI’s trademarked thermal decomposition technology processes whole car tires into valuable raw materials and energy sources such as carbon, flue gas, oil and steel. Cement producers can use fuel generated in this process to operate their kilns.

Bilfinger Tebodin used the combined expertise of process engineers, Process Safety and Licence to Operate consultants and sustainability specialists to understand PRTI’s process and then conceptually re-design it. One of the challenges was to extract the end materials from the reactor in a way that is safe both for the workers as well as for the environment. By installing process control configurations, parameters such as temperature and oxygen levels are continuously monitored and controlled. The occupational and process safety is safeguarded and e.g. the risk of Loss of Primary Containment is reduced to an acceptable low level. Furthermore, the Bilfinger team was able to suggest design changes that can increase the Overall Equipment Effectiveness (OEE) of PRTI’s plants.

Burning tires directly to fire cement kilns results in various environmentally harmful emissions. By installing PRTI’s thermal decomposition technology at their plants, cement producers can continue to use tires as a cost-efficient energy source while lowering their emissions.

At the same time, the technology helps to make use of the millions of tires that are newly produced each year, but due to very high quality standards never make it to the road. Up to 10 % of total tire production is rejected and marked not suitable for use in traffic.

In the future, Bilfinger could continue to support PRTI in bringing its technology to Europe, as Bilfinger can cover a wide range of industrial services: from process design and engineering via permits and safety evaluations through to the actual construction and maintenance of plants.

//www.bilfinger.com" target="_blank" >www.bilfinger.com:www.bilfinger.com