CFD-based new developments and optimization of filter installations

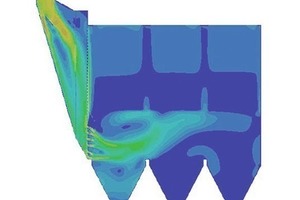

Intensiv-Filter continued to set the course as a leader in dedusting technology. From now on, filter installations and plant-components will be optimized with the in-house CFD-program. The potential of CFD helps to predict the real characteristics of the flow and ensures the efficiency of the filter (Fig. 1). The parameter of the stream flow helps to increase the energy efficiency of the dust removal installations and components.

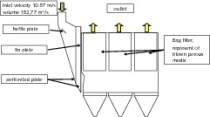

Using the example of the inlet stream, Figure 2 shows the initial situation of the dust removal installation. Using CFD, the alternative shows clearly which fluidics optimizations are achieved with constructive changes (Fig. 3). After evaluating and analyzing the CFD data, baffle plates are placed at the most optimal positions. The construction of the raw gas inlet is enhanced due to the fluidics parameter. The loss of pressure is evidently minimized with a more homogenous stream. This in turn leads to less energy consumption.

“Intensiv Filter is already using CFD for new developments of Jet Pulse bag filter systems and plant components, but up to now has relied on the services of external suppliers. From now on the engineers of the Intensiv-Filter development department will use the CFD-tool of a leading provider in-house. A CFD-expert group will work closely with the constructional department. The software offers a direct path from 3-D CAD to the CFD-geometry. The calculations of even complex tasks with more than 1 million nodes are ensured. Besides the simulations of fluids the CFD software also allows the thermal dynamic optimization, for example air to air-cooler, the simulation of multiphase streams or for example the design of conditioning towers. Energy efficient dedusting filter systems can only be developed with the knowledge of the velocity, pressure profile and the stream of particles. In this way, Intensiv-Filter increases their core-competence in dedusting. The decision to implement CFD-analysis in-house is especially a tool to improve performance and to shorten the time requirement for customized solutions in optimizing the dynamics of gas- and solid-streams. The optimization of the installation is possible with high accuracy from the point of emission up to the stack”, according to Dr. Gunnar-Marcel Klein, the technical director.

When used professionally, the numeric fluid simulation is a valuably instrument to accelerate the development process and to optimize the product. In addition risks in development will be reduced. CFD is a standard tool for solutions of fluidics functions.

www.intensiv-filter.com