Calcined mixture of clay and

limestone as a complex additive

for blended Portland cement

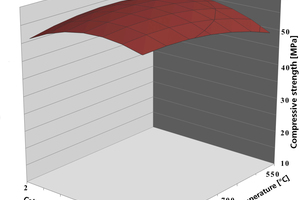

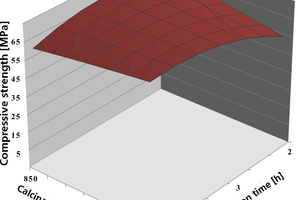

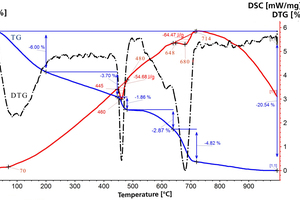

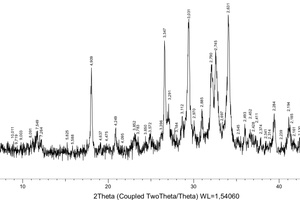

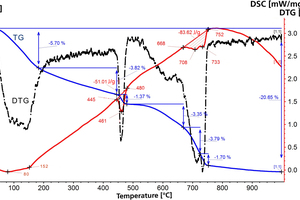

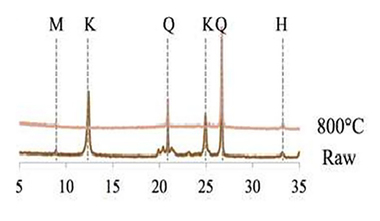

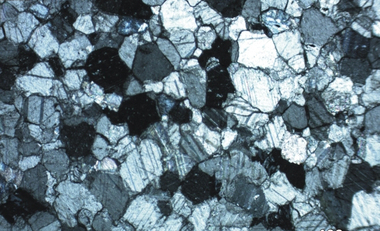

Today, the main direction in the cement industry for saving both resources and energy is the development of low-clinker or blended cements using one-component and complex mineral additives. Promising raw materials for obtaining such additives are calcined polymineral clays, which are widely abundant, readily available, and used either separately or in combination with limestone. The purpose of this work is to create an effective complex additive based on a calcined mixture of clay and limestone. The results of research show the influence of the complex additive on blended cement stone properties. The optimization of parameters for obtaining the complex additive was based on mathematical experiment planning. As a result of pertinent research, it has been established that the strength of cement stone containing a complex mineral additive depends on the content of kaolinite in the initial clay and on the calcination parameters. The additive content was 20% of the Portland cement weight.

1 Introduction

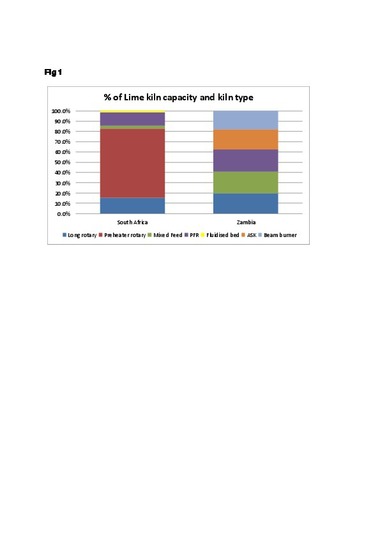

Portland cement (OPC) is the primary hydraulic binder used in construction. However, its production is characterized by high energy and resource consumption and involves significant amounts of polluting emissions. One of the most effective and recognized approaches to solving these problems in the cement industry is the development of low clinker blended Portland cement with mineral additives. Currently, the average content of mineral additives in Portland cement is about 20 %. The predicted increase in the global production of Portland cement, coupled with the increased dosage...