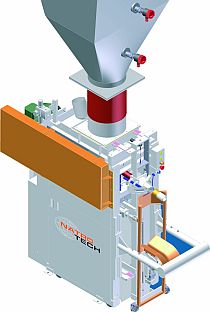

Cascade solution for efficient fillinig

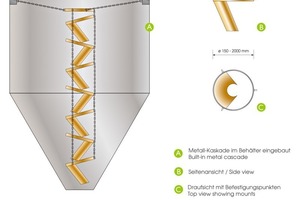

Whether for the chemical or pharmaceutical industry, for the filling of materials or for the food industry – the flow-stop construction of Listenow is suitable for many fillings, whether lumpy, powdery or granular. The design is manufactured to customer requirements and can be built depending on the use from painted or galvanized steel. The filling unit is permanently installed in the production unit and can be cleaned very easily. To prevent the filling material from impinging on forming angles of repose, the individual cascades are set in a way so that they can pass on the material at a minimum distance and consequently with no larger free height of fall. Simultaneously, the flow rate is regulated by changing the angle of the cascade to prevent segregation. The special geometry of each cascade allows an overflow during the filling, so the containers are completely filled.

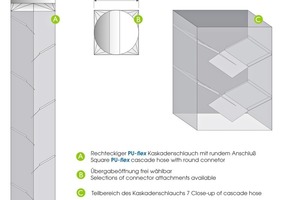

The vast experience of the Swabians in the production of polyester filling hoses from different tissues with different coatings allows other interesting applications, including those from PU-flex in different material thicknesses. In combination with Flow-Stop thus gentle feeders for ground material can be produced, e.g. on sensitive swash plate sieves, or tetra pack lids can be transported to continuous packaging machines. The transparency of the poly-urethane film permits permanent monitoring of the charge by the staff or by means of sensors.