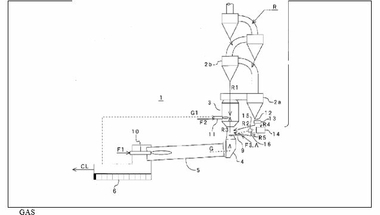

Cement burning apparatus, and method for denitrating exhaust gas from cement kiln

(22) 08.01.2015

(43) 11.09.2015

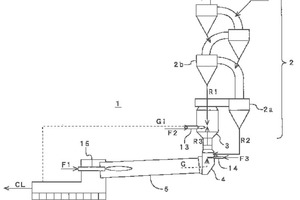

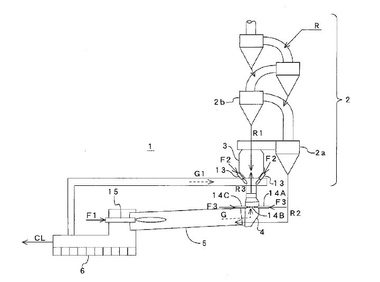

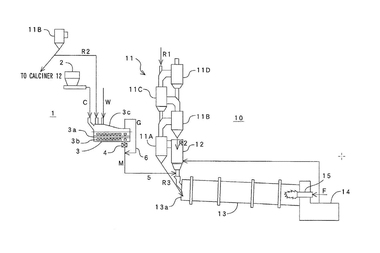

(57) [Problem] To efficiently reduce the concentration of NOx in an exhaust gas from a cement kiln while keeping the burned state at a good level regardless of the type of a calcining furnace to be used. [Solution] A cement burning apparatus (1) equipped with a burner (14) for blowing a fuel (F3) and combustion air into a kiln tail part (4) of a cement kiln (5) to burn the fuel. It becomes possible to reduce NOx, which is contained in an exhaust gas from the cement kiln, in a low-oxygen zone in the kiln tail part, and it also becomes possible to improve the decarbocxylation efficiency of a cement raw material due to the burning of the fuel. The burner may be equipped with a swirl vane (a swirl means) (14b) for swirling a mixed flow of the fuel and the combustion air. It is preferred that the amount of the fuel to be supplied into the kiln tail part of the cement kiln is 20 % of more and less than 50 % of the amount of the fuel to be supplied into a calcining furnace (3) that is provided in the cement kiln. The fuel to be supplied into the kiln tail part of the cement kiln may comprise at least one of pulverized coal, a heavy oil and a burnable waste material.

(71) Taiheiyo Engineering Corporation, Tokyo (JP)

(84) ARIPO (BW GH GM KE LR LS MW MZ NA RW SD SL ST SZ TZ UG ZM ZW), Eurasian (AM AZ BY KG KZ RU TJ TM), European (AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR), OAPI (BF BJ CF CG CI CM GA GN GQ GW KM ML MR NE SN TD TG)