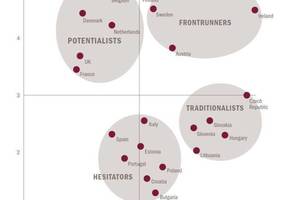

Cement industry is well equipped for Industry 4.0

This is the conclusion of a study conducted by RWTH Aachen University, which has analysed the situation in the German cement industry (from page 14).

In “Industry 4.0 in the Cement Industry – Status Quo and Prospects”, German cement producers are attested a high level of digitalization in the production process, on which Industry 4.0 can build on. In the scope of this study, it was noted that the shortage of skilled specialists poses a major challenge in the realization of Industry 4.0 in the cement industry. The industry faces the challenge of finding competent young professionals and attracting their interest in working in cement plants or even in the industry’s supplier sector. An excellent opportunity for this is the ZKG field trip, which we plan to arrange again this year. We are still looking supporters for this.

In respect of downstream value creation chain, the study sees a trend towards increasing automation in the production and use of concretes with new technologies in the concrete and construction industries. We want to report on interesting projects in which new technologies or products can make even more from cement as a material. On page 58, we present a project in which infra-lightweight concrete has made the leap from the research phase to practical use in construction.

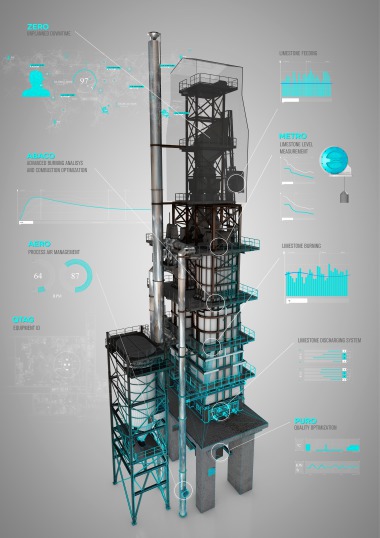

Not only in the cement industry is digitalization of the branch being pushed ahead. The lime industry is also engaging intensively with this topic. At the last ILA General Assembly in South Africa, digitalization was a key focus. Three suppliers of lime kilns presented their concepts in respect of digitalization. Two of these are presented here in this issue. From page 36, Stephan Lechner answers the question “How is lime production impacted by digitalization?” Luca Sarandrea is presenting, for example, the newly developed BOT (from page 40).

But even with all the data acquisition, collection and evaluation, we should, of course, not forget the basics. Lime production is a complex process that, independent of any digitalization, requires in-depth understanding. With his article “Comprehending the lime production process” Dr.-Ing. Georg Kehse wants to increase awareness of this and pass on his field experience to industry newcomers (from page 48).

Last but not least, from page 54 we present a new initiative. This new initiative to be launched at Hannover Messe 2019 sees Singapore Economic Development Board (EDB), McKinsey & Company, SAP, Siemens and TÜV SÜD collaborate to support companies in scaling the adoption of Industry 4.0 technologies.

Yours

Anett Fischer

Editor-in-Chief