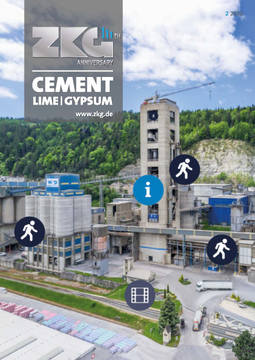

Cement plant can be virtually walked through for the first time

As part of its digitalization offensive, w&p Zement has taken the next step towards external transparency: People interested in production can now conveniently visit three different w&p locations via their computer or smartphone. This was made possible by the complete reconstruction of the respective sites using innovative 3D photo technology. As a digital guest, visitors now also have access to those areas that cannot be entered during regular tours for security reasons. In addition to the virtual tour, various integrated info points provide detailed information, for example on the mining of raw materials or on how the rotary kiln works. The virtual tour is currently available for the w&p cement sites in Wietersdorf and Peggau as well as for the w&p ready-mix concrete plant in Gratkorn.

The w&p plants are always open to interested parties for plant tours. However, the virtual plant now offers even more transparency and builds proximity to the production sites. With the playful access, different interests can be precisely addressed. “It was important to us to make our production sites accessible to everyone. Especially in times of pandemic, the virtual plant brings even more advantages. At least we can continue to offer digital tours to schools and universities – regardless of current safety regulations,” reports Peter Ramskogler, Sales Director of w&p Zement.

The tours of the Wietersdorf cement plant (Carinthia), the Peggau cement and lime plant (Styria) and the Gratkorn ready-mix concrete plant (Styria) can be viewed at https://alpacem.com/360/.