Characterization of the microstructure and

mineral phases of German iron and steel slags

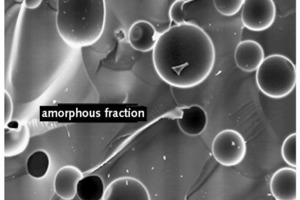

Summary: This work characterizes the mineral composition, amorphous fractions and microstructure of various iron and steel slags by chemical analysis as well as by X-ray diffraction and electron microscope investigations. The results show that different German iron and steel slags differ in their chemical and mineralogical compositions as well as in their characteristic parameters, such as basicity and proportion of amorphous constituents, and in the levels of periclase and free lime that are responsible for possible changes. The investigations have been carried out so that iron and steel slags can be put to appropriate use in the building materials industry. In particular, it was intended that the iron and steel slags could be used to reduce the risk of an alkali-silica reaction (ASR) in concrete.

1 Introduction

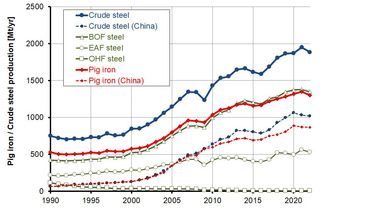

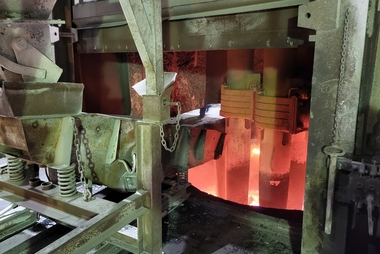

The recycling of iron and steel slag is currently an urgent and important problem for all scientists throughout the world, but particularly for Chinese scientists. In Germany there is already a great deal of experience with the recycling of iron and steel slag. The tests to characterize the microstructure and mineral phases of German iron and steel slag from different production processes have provided practical guidelines for improving the quality of iron and steel slags in other countries, especially China. Good quality is an essential requirement for effective and...