Current research findings on calcium-silicate unit production technology

The German research association Forschungsvereinigung Kalk-Sand e.V. (FVKS) has been involved in the development, production and testing of calcium-silicate masonry products for over 50 years now. Its paramount goals are to continuously improve and develop calcium-silicate production technology and construction applications. Its main tasks are to promote damage-free construction, further improve product quality, encourage innovative developments and identify measures for further reducing both the cost of production and energy consumption. This AiF research project provides an overview of the industry’s activities geared to practical implementation of those set goals.

1 Introduction

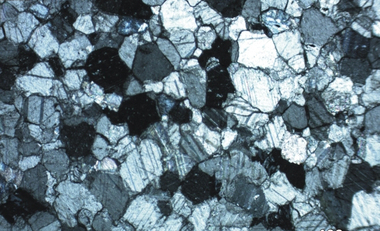

Calcium-silicate (CS) units are made from the starting materials sand, lime and water. The raw materials are proportioned by weight, intensively mixed together and fed into reactors on a conveying system. Within the reactor, quicklime is quenched under water consumption to obtain hydrated lime. The green units are then hardened under steam pressure at temperatures of the order of 200 °C for about four to eight hours, depending on the product’s geometry. The hot, steamy atmosphere dissolves silica from the quartz-sand grains, and the silica forms crystalline CSH phases with the...