Ecology or economy?

When I started as a pyro-process engineer in the cement industry 26 years ago, the number of projects dealing with technologies for increased firing of alternative fuels (AF) was still rather small. Even though the German and Austrian cement industry already had conceivable substitution rates, the co-processing of secondary or alternative fuels was still a secondary subject compared to NOx-reduction, energy consumption and production capacity.

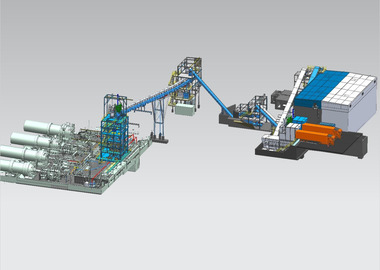

Today, AF is one of the most dominant subjects for the cement industry – and rightly so, because it is a perfect example to refute the traditional dialectics that ecology is a contradiction to economy. Firing AF in appropriate cement plant equipment decreases waste dumping, the use of fossil fuels, fuel costs and sometimes even the emission of pollutants. Obviously, nothing comes without a price tag, but when set up consciously with the right technology and within the right strategy, the use of AF can make a huge contribution to both the individual economy of the cement plant as well as to the environmental friendliness of the whole of society. Accordingly, AF firing – sometimes referred to as co-processing – is considered a prominent action line in all major CO2-reduction roadmaps.

Working in an industry with such a huge environmental impact, we are often increasingly confronted with the allegation of spoiling the environment. Certainly, most people are not aware of the importance that cement and concrete also has for their own lives. All attempts to substitute concrete as a building material will have certain limitations and I am sure there is no future without cement. However, it is certain that the cement industry also has no future if it does not actively support environmental aspirations. My wish would be that we should always try to build a bridge between ecology and economy.

Yours sincerely,

Matthias Mersmann