Alternative fuel system for kiln riser duct firing at CRH Slovakia

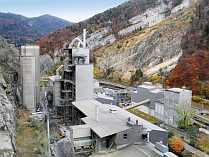

In 2017 A TEC and CRH Slovakia have installed an alternative fuel system for kiln riser duct firing in Turňa nad Bodvou/Slovakia. The Turňa nad Bodvou cement plant has already operated a SAF system for the main burner which consists mainly of a double truck docking station and a dosing system.

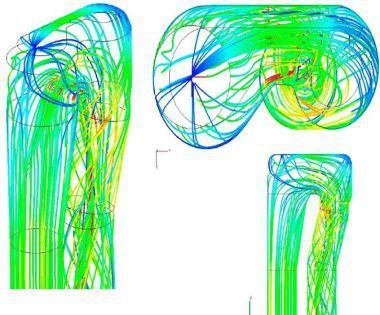

The riser duct itself has a gas retention time of approx. 3 sec, so up to approx. 25 % TSR at the riser duct are possible by limitation of the material to max. 50 mm (2D) size. The SAF is now injected above the bypass take-off point (in the location of the current meal inlet). To limit the CO emissions, a hot ignition zone has been created at the SAF injection. This was realized by moving the existing meal inlets to the riser duct height of about 8–10 m.

As the kiln is equipped with an extended kiln riser duct (without tertiary air) it is possible to fire a significant amount of fuel in this kiln riser duct. Now about 25 % of the total fuel as SAF with main burner quality can be fired in the kiln riser.