Effect of ball load and size distribution on grinding and classification performance

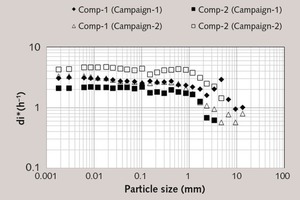

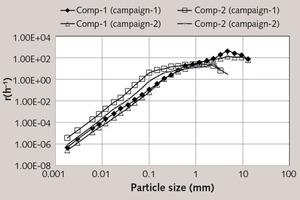

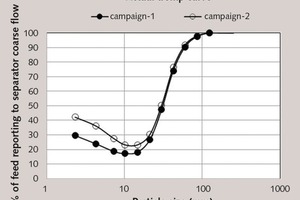

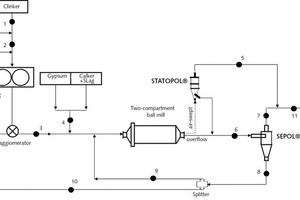

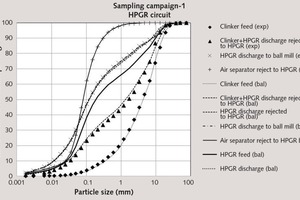

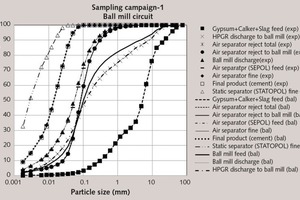

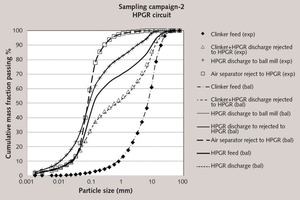

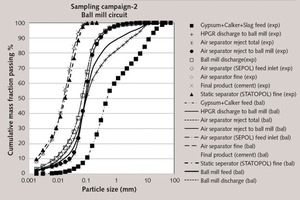

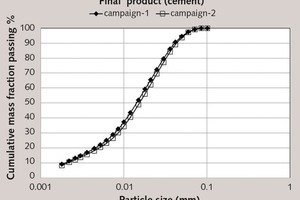

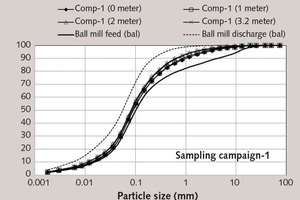

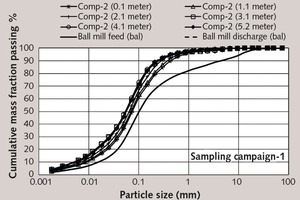

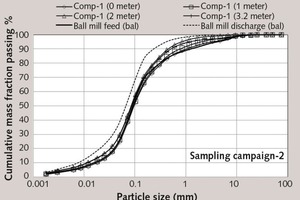

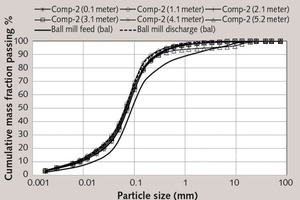

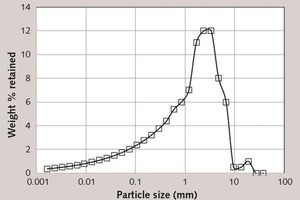

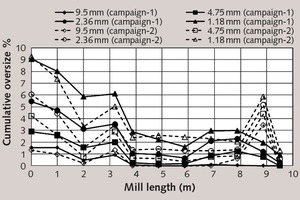

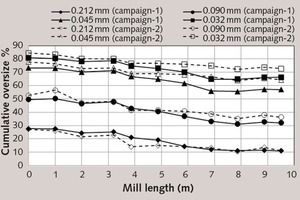

An industrial test work was performed to analyse the effect of applying a lower ball load and a finer ball size distribution in the second compartment of a KHD Humboldt Wedag® ball mill on grinding and classification performance of a hybrid high pressure grinding roll (HPGR)/multi-compartment ball mill cement grinding circuit. Mass balance of the circuit was done by JKSimMet Steady State Mineral Processing Simulator. Specific discharge and breakage rate functions were estimated by using a perfect mixing modeling approach [1]. The performance of the dynamic air separator was determined by using an efficiency curve approach [2].

1 Introduction

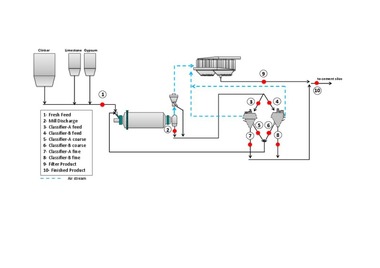

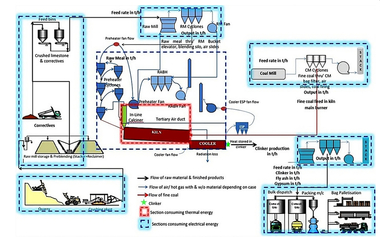

Ball mills are known to be the highest energy consumers in cement grinding circuits. Inefficient grinding conditions prevail especially in the second compartments of multi-compartment cement grinding ball mills. Thus, energy efficient grinding mills such as high pressure grinding rolls (HPGRs), vertical roller mills (VRMs) and Horomill® etc. are introduced and integrated to the cement grinding circuits to reduce the specific energy consumption of cement grinding. HPGRs are usually used as pre-crushers ahead of ball mills in different configurations [3] to reduce the size of the...

![18 Applied two-compartment ball mill model structure (Redrawn after Genç and Benzer, [19])](https://www.zkg.de/imgs/tok_823dc85bbce5bb47ac4c175ba547dcfb/w300_h200_x400_y100_101548685_75fa94dda7.jpg)