Effect of oil shale additions on the raw mix and clinker for high belite cement

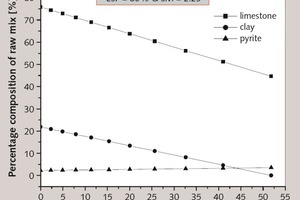

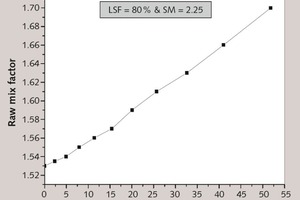

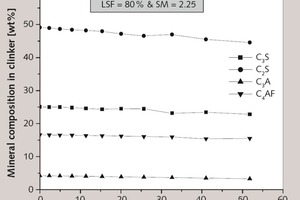

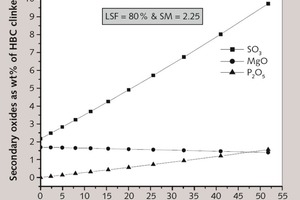

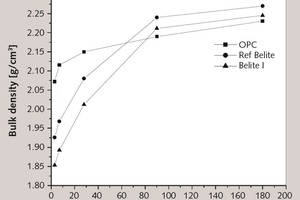

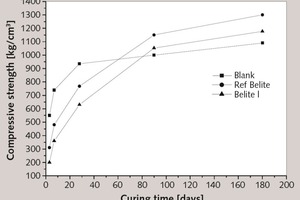

Raw mixes for high belite clinker were designed on the basis of the chemical analyses of Egyptian raw materials, with and without considering any additions of Egyptian oil shale. The oil shale investigated was supplied from the Younis Gharb mine at the Red Sea coast; it is of a moderate calorific value (≈ 2500 kcal/kg shale) and its ash content is about 60 % of its weight. The criteria for the raw mix design were the lime saturation factor LSF = 80 % and the silica modulus SM = 2.25. The study emphasized that the high belite clinker prepared with and without added oil shale has very acceptable properties and that oil shale has only a slight effect on the physico-mechanical properties of the clinker produced. The study helps to evaluate the use of oil shale as a substitute fuel in a kiln plant for producing high belite clinker.

1 Introduction

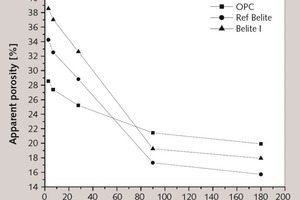

High belite cements are characterized by their relatively high content of belite and low content of alite without sacrificing the early strength in mortar and concrete. For high belite cements the range of LSF in the raw mix has been defined as 78 to 83 % [1].

Interest in high belite cements probably dates back to the early seventies; such interest has intensified due to the following properties:

Lower alite content in the belite clinker with an accompanying clinkering temperature that is about 100–150 °C lower than that required for ordinary Portland cement (OPC) clinker. The...