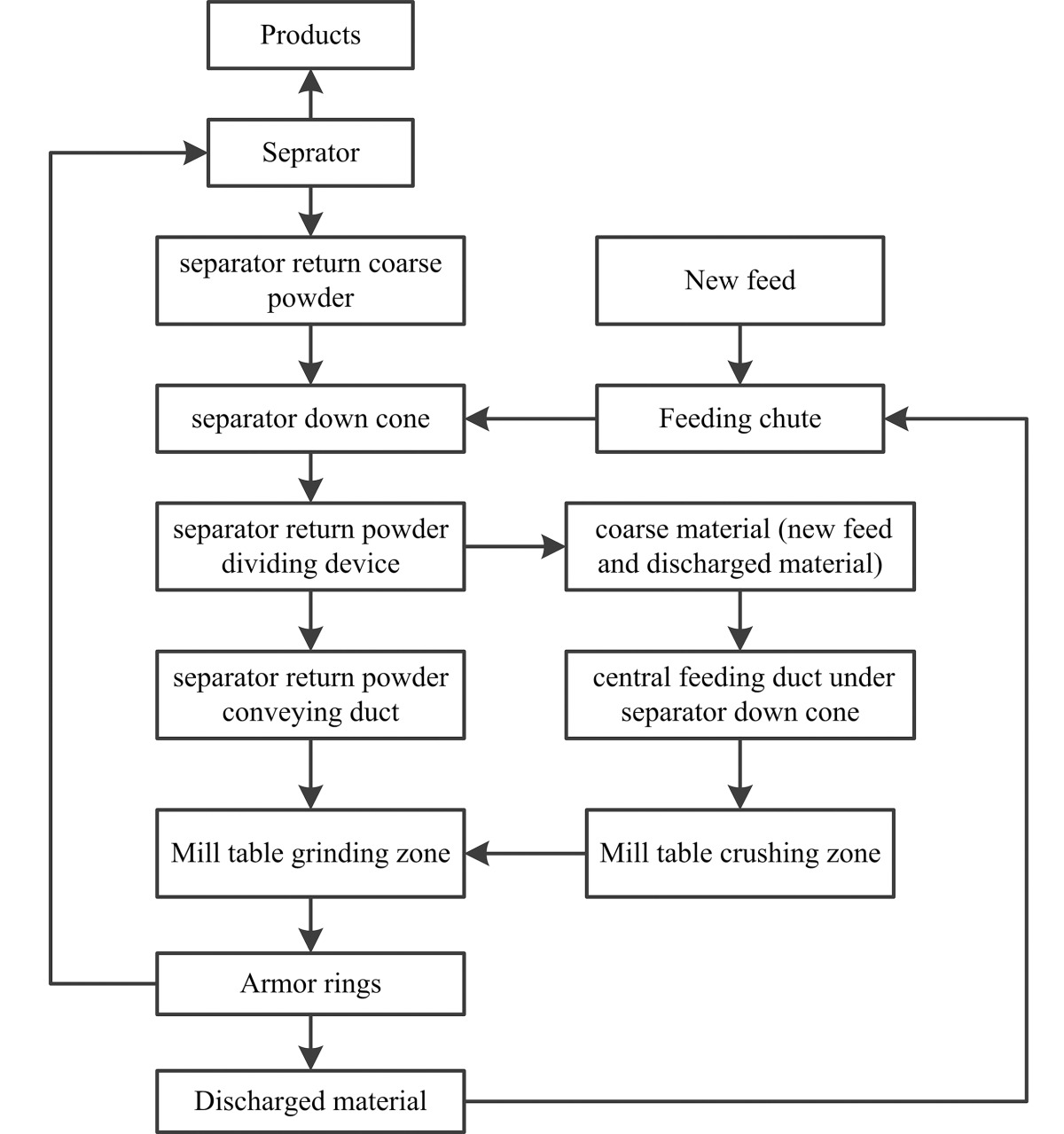

Energy-efficient cement production using an extremely coarse raw mix – Part 1

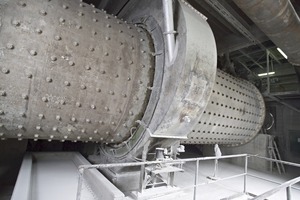

A field test has demonstrated that energy can be saved and production increased using the coarse grinding process.

Operating experience with a production method using extremely coarse raw material grinding indicates that the continuously increasing technical challenges for the saving of energy and fuel in conjunction with continuously more stringent environmental regulations can be conclusively overcome. Following a survey of experience gained in East European plants, at which double-digit percentage energy savings were achieved, this article reports on a multi-day operational test using the coarse grinding process in an Austrian cement plant. Mill output was increased by up to 40 % (from 57 to 80 t/h) and...