Flexco designs precleaner and secondary cleaner for extreme requirements in underground mining

Underground mining conditions can be extreme for man and machine – and high temperatures are just one of the challenges to be overcome. Flexco Europe GmbH offers conveyor belt system operators special solutions that can safely withstand the heat, including various blades for precleaners that still work reliably at 230°C. Dust and gases can cause explosions underground, so Flexco designs the precleaners to comply with ATEX if required.

The manufacturer is a leading international supplier of mechanical conveyor belt fastener systems, belt cleaners, belt trainers, impact beds and pulley lagging used by companies in a wide range of industries, including the mining sector.

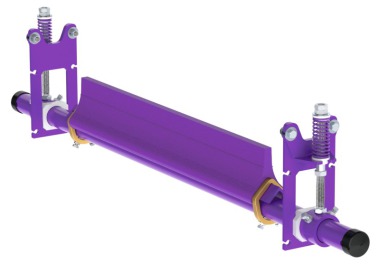

Flexco has developed various cleaner blades for the precleaners and secondary cleaners of the EZP1 and MSP series, enabling operators to react to the often extreme temperatures – and not only in the minus range. Operators have access to various polyurethane versions, including a bright yellow variation for high temperatures. It allows continuous operation up to 135°C and up to 163°C for short periods. There is also a deep red ultra-high-temperature cleaner blade, which performs reliably at peaks of up to 230°C. “Belts can be exposed to such high temperatures when transporting coal, clinker or cement,” reports Jonas Zahn, Product Manager Heavy-Duty at Flexco.

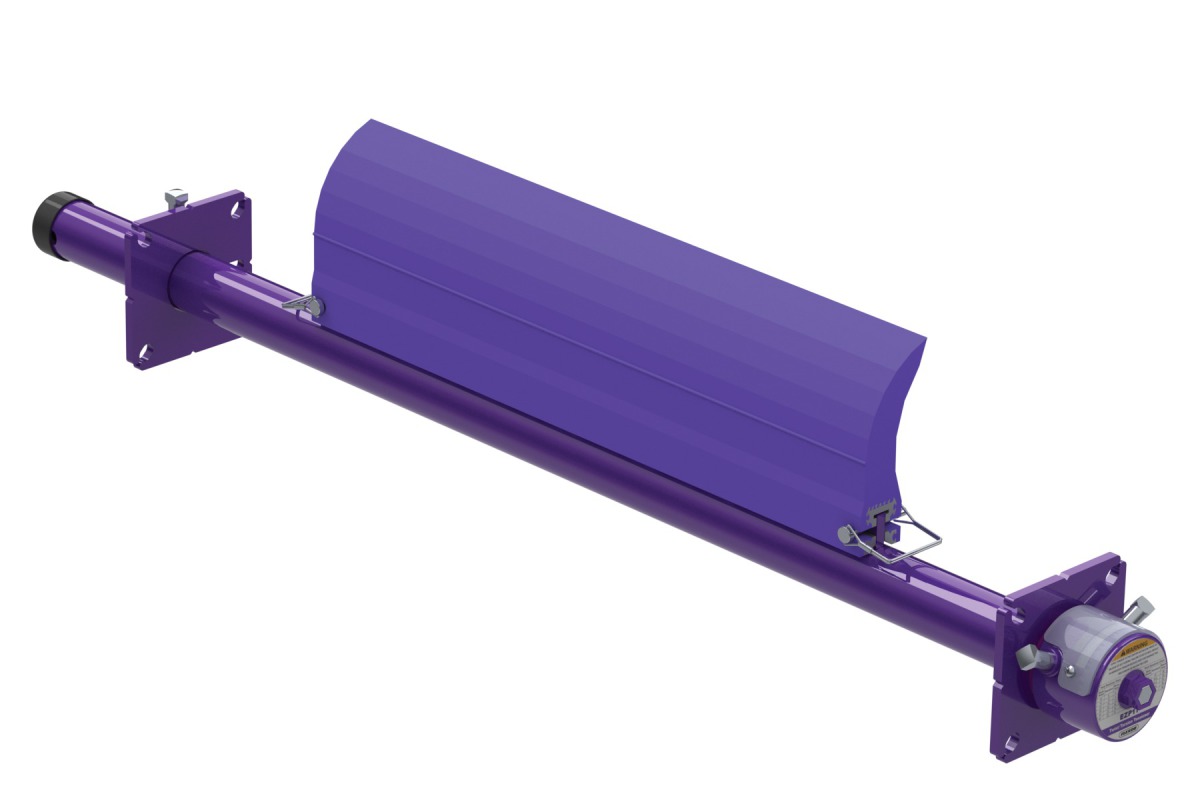

In addition to the scrapers of the EZP1, MSP and MMP series, Flexco also designs the H and R types as well as the MHS ATEX-compliant series. Many safety measures have been incorporated in these designs to provide the greatest possible degree of work safety. For example, the EZP1 cleaner can be easily attached to the conveyor belt or feed station using universal mounting plates. However, it can only be mounted on a grounded conveyor structure. This is because Flexco manufactured this component from conductive material. Flexco has documented in detail for its customers how the user can ensure grounding and how he can attach the cleaner to the supporting structure.

//www.flexco.com" target="_blank" >www.flexco.com:www.flexco.com