Fluidized calcination furnace

(22) 25.12.2013

(43) 04.11.2015

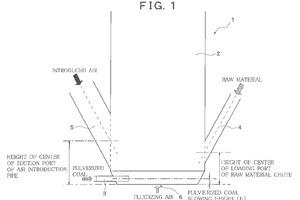

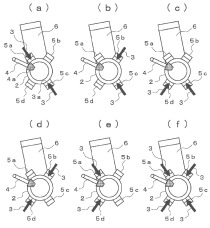

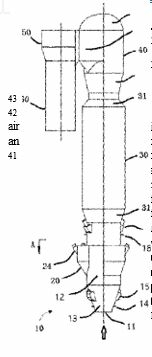

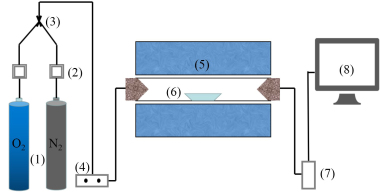

(57) A fluidized calciner is provided which allows a reduction in the rate of unburned fuel at on outlet of a fluidized calciner to enable sufficient calcination while preventing possible occlusion in a preheater, even when pulverized coal of coal or coke, which has low combustion quality, is used as fuel, based on calculations in accordance with computational fluid dynamics based on the shape of on actual furnace and operational conditions. The present invention provides a fluidized calciner including a tubular furnace body (2) in which an axial direction is an up-down direction, a pulverized coal blowing line (3) through which fuel is blown into the furnace body (2), a raw material chute (4) through which a cement raw material is loaded into the furnace body (2), at least one air introduction pipe (5) through which introduced air is sucked, the pulverized coal blowing line (3), the raw material chute (4), and the air introduction pipe (5) being connected to a side portion of the furnace body (2), and a fluidizing air blowing port (6) disposed at a bottom portion of the furnace body (2) and through which fluidizing air is blown into the furnace body (2), in which a blowing port of the pulverized coal blowing line (3) is disposed below a suction port of the air introduction pipe (5) and above the fluidizing air blowing port (6).

(71) Mitsubishi Materials Corporation, Chiyoda-ku, Tokyo 100-8117 (JP)

(84) Designated Contracting States: AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR Designated Extension States: BA ME