The contract for the National Cement Co. (NCC) cement plant (Fig. 1; Table 1) was signed in September 1974 and the plant was opened on 01.08.1978 by HH Sheikh Rashid Bin Sayeed Al Maktoum. It was converted from the wet to the dry process on 01.07.1984. A large project was the production of cement for the Burj Khalifa project, up to now the tallest building in the world.

Today with an annual production capacity of more than 1.5 million t of cement, National Cement is clearly one of the leading cement manufacturers in the UAE. The company produces ordinary Portland cement – conforming to BS 12/1996 and ASTM C-150, Type-I, high sulphate resisting Portland cement – conforming to BS 4027/1996 and ASTM C-150, Type-V, moderate sulphate resisting Portland cement – according to ASTM C-150, Type-II, Portland blastfurnace cement – conforming to BS 146/1996 and high slag Portland blast cement – conforming to BS 4246/1996. White aggregates with a particle size of 0–20 mm are generated as a by-product.

NCC implemented the advanced ERP solution SAP R/3 (System Application and Products in Data Processing) ensuring consistent quality control at every stage of production. In addition, the plant is well supported by a powerful in-house modern laboratory with the latest state-of- the-art equipment available on the market, for quality control and continuous improvement of the products. The laboratory includes the latest equipment such as XRF/XRD analysers for determination of the cement fineness and particle sizes. In addition to the well-equipped and furnished chemical and physical laboratory, the company has a highly qualified staff with long experience in the field of cement who are absolutely dedicated to their work.

Raw materials

Limestone is brought from the Rawda Hatta quarry which is about 90 km away from the plant. There is an inland sand quarry at Al Habab about 45 km from the plant. Limestone, sand and laterite are stored in open yards. An additional raw material is copper slag. The limestone is fed to two different crushers; a gyratory crusher (700 t/h; Fig. 2) and a double rotor hammer crusher (450 t/h). There are two ball mills for raw material grinding at the plant, both with a capacity of 175 t/h. The raw meal is stored in two silos with 12 000 t capacity each.

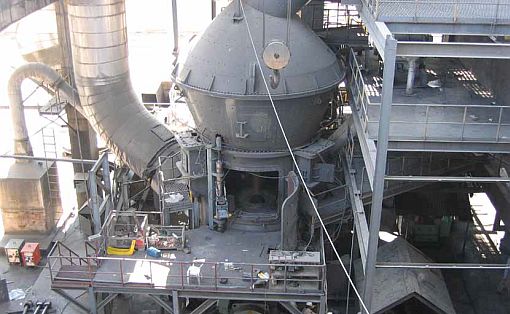

Kiln line

The kiln is an FLSmidth Rotex kiln (55 m length, 5 m diameter) with a capacity of 4000 t/d (Fig. 3). Coal is fed as the main fuel to the preheater and main burner. The preheater has an in-line calciner and is a four-stage, single-string cyclone preheater. At the transfer point to the kiln system, a properly designed quench mixing chamber (Fig. 4) is critical for the highest performance efficiency and minimum interference to stable kiln operation. This quenching chamber has traditionally only been used in regions where the local raw materials are naturally high in chloride, sulphur or alkalis. FLSmidth has developed this type of chamber through a number of innovative design features. At NCC, for the first time an updated design of an FLSmidth quenching chamber has been used very successfully. Also, NCC has used as alternative fuels, used car tyres (Fig. 5), which are fed to the kiln inlet (full piece) by weighing system and double flap gate directly to the inlet kiln at the riser area. The clinker is cooled in a cooler type SF designed and supplied by FLSmidth.

Coal grinding plant

At the beginning, the National Cement plant used Heavy Fuel Oil (HFO) which at that time was available to all plants at reasonable prices. Later on, with the development of grinding systems, it became obvious that vertical roller mills are perfectly suitable for the comminution of cement raw material, cement, granulated slag as well as coal. From the energy aspect and due to its flexibility, the vertical roller mill – considered as a closed system consisting of a comminution zone (grinding rollers, grinding table, dam ring), a drying zone and a classification zone – is much more preferable to a ball milling system. Due to the compact design of the vertical roller mill, failures in the material transport are eliminated and this has a direct influence on the availability of the plant. As a result, with the increasing prices of Heavy Fuel Oil (HFO), the NCC management considered the above-mentioned factors (energy saving etc.) and decided to establish a coal grinding plant with a vertical mill (Figs. 6 and 7). For this project, the NCC management has co-operated with very well-known companies in the cement industry: Loesche, FLSmidth-Pfister, Aumund, FLSmidth, Intensiv-Filter and Venti-Oelde.

The project consisted of various activities, therefore, to optimize the process and carry out the project successfully required a multidisciplinary team under the guidance of a leader. The NCC management made the contracts with all the suppliers whereby Loesche provided the basic engineering for the complete grinding plant incorporating all the equipment as well as the coal mill. The commissioning was planned to take place within 4 months after receiving all the equipment and fabricated steel structures. Finally, on the 22nd of May 2012 commissioning started and the plant was put into operation.

The core equipment of the coal grinding plant is an Aumund Samson feeder and a Loesche coal mill type LM 28.2D. From the Samson feeder the material is extracted by a bucket elevator and a belt conveyor to the raw coal feeding bin. From there the material is extracted to the weighing systems and by a screw conveyor to the mill. In the mill the coal is ground, dried and the coal dust is classified. Hot gas from the kiln is used for the drying of the coal. From the mill, a filter from Intensiv Filter extracts the fines and returns the coarse material to the mill. The fines are stored in another bin, and can be dosed with two Pfister rotor weighfeeders (Fig. 8), one for the kiln F. L. S. Duoflex burner and one for the calciner. In addition to coal, carbon dust from the aluminium industry is used as a supplementary fuel.

Clinker storage

The clinker is stored in a concrete dome circular silo, in two steel silos and one clinker structural steel dome storage silo.

Cement grinding

The cement grinding is carried out with two ball mills with a capacity of 100 t/h and 150 t/h, respectively. For the drying of the slags a flash dryer is used. Slag is pre-ground separately in a beta mill from Cemag (Fig. 9) and then fed to the tube mill for finish grinding. The combined use of the beta mill for pre-grinding saves about 15 % power and in turn increases the throughput to 15 %.

Cement storage, despatch and filtration

The cement is stored in three concrete silos (5500 t) and four steel silos (1650 t). Four packing machines from Haver & Boecker are used for cement packing, two have a capacity of 120 t/h and two a capacity of 90 t/h. Bagfilters are used as the main filters. There are also two ESP filters, one for the kiln and one for the bypass (converted to a bag house system).

Conclusions

The project for the coal grinding plant is a good example of the activities of the plant personnel to keep the production updated and innovative. New concepts are continuously validated by the plant personnel. The key is not just thinking ahead, but also being one step ahead.