Improving cement plant performance with O&M contracts

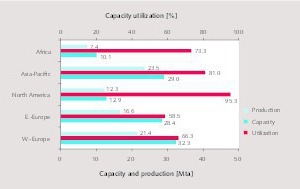

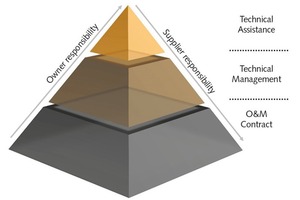

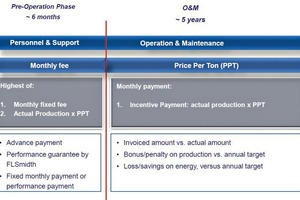

Decreasing capacity utilization rates and financial constraints are reasons for the ongoing performance improvements of cement plants. However, when technical solutions are getting more complex and when operational know-how is limited, O&M contracts can be the solution. This article will look at this approach more closely.

1 Introduction

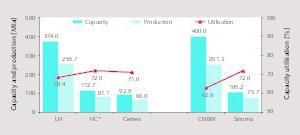

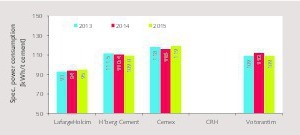

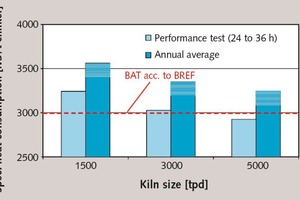

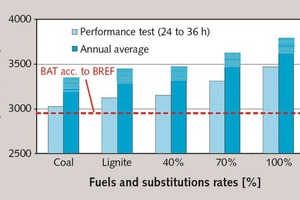

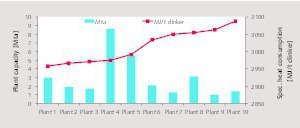

Cement plants differ in plant age, size, technology, automation, fuel supply, operational and maintenance requirements and other issues. Generally, more CapEx is spent on the latest technology (Figure 1), to reduce operational and maintenance costs. Sometimes it is very difficult to compare individual plants. Plants with several kiln lines (Figure 2), which use identical raw materials, can compare the efficiency of the individual kiln lines more effectively than an isolated plant with just one kiln line. The best performing plants often perform best in only one or two parameters,...