Influence of the granulation conditions and performance potential of granulated blast-furnace slag – Part 1: Granulation conditions

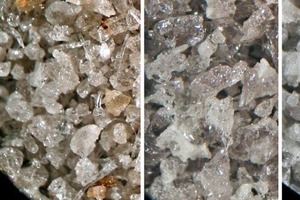

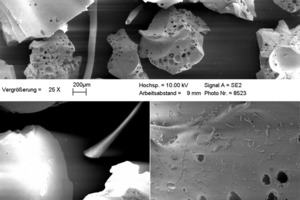

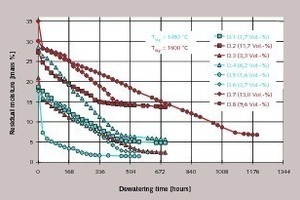

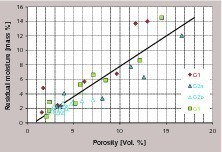

Laboratory granulation is highly suitable as a means of demonstrating both the influence of different chemical compositions of granulated blastfurnace slags on their reactivity and the influence of different granulation conditions on the physical properties of granulated blastfurnace slag. The first part of this article deals with the granulation conditions.