Investment in emissions reduction

thomas zement GmbH & Co. KG is an important business segment of the thomas gruppe: Customized cements in reliable product and delivery quality are produced for the customer. The thomas gruppe is a family-run company in the construction and building materials industry. With more than 80 locations in Germany, Denmark and Poland, thomas gruppe operates in the fields of cement, precasted concrete parts, ready-mix concrete, asphalt stone and road construction.

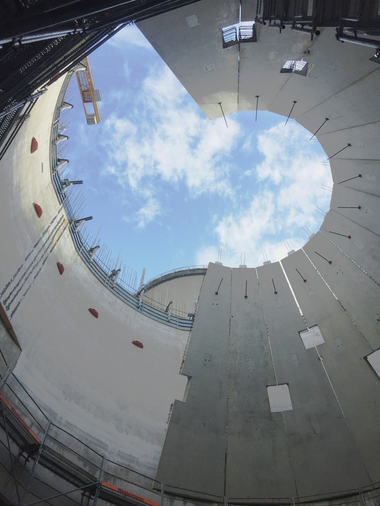

In January 2018, thomas gruppe took over a traditional and family-run cement plant in Erwitte and launched a substantial investment program. The first decisions here were aimed at reducing emissions. The starting signal was given in June 2018 with the order for a turnkey plant to reduce gaseous emissions in the flue gas. The plant has already started stable regular operation in April 2020 and contributes, among other things, to minimize NOx and NH3 emissions.

The investment comprised two new SCR denitrification units, including the flue gas transport system incorporating newly designed filter fans, and the technology for adding the reducing agent.

The existing SNCR system in the raw meal preheater was optimized and is an integral part of the emission reduction concept. By modifying the filter systems and changing the process control, not only the gaseous but also the dust emissions at the Erwitte site were reduced to a considerable extent.

Further measures, in particular changes to the raw material feed system, have also led to an enormous reduction in total C emissions.

As a result of these investments, the Erwitte plant of thomas zement is one of the most environmentally friendly cement production facilities in Europe.