Iron-bearing composite added to raw-material flour

in the Portland clinker production process

(22) 05.06.2018

(43) 16.12.2019

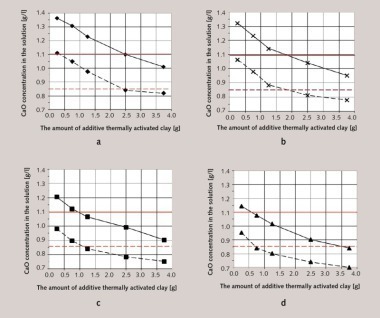

(57) The subject of the application is an iron-bearing composite used in the production of Portland clinker. This composite is a mixture that contains fine-grained waste dry or wet dust from the dedusting of metallurgical or foundry furnaces, which are subjected to a mixing process as iron-bearing components that are by-products of metal smelting. The mixture resulting from the combination in the process of mixing waste fine iron-bearing components contains 60 to 85 % Fe2O3, with granulation up to 100 % by weight grains up to 1.00 mm in diameter and up to 10 % by weight grains up to 2.00 mm in diameter. The iron-bearing composite mixture is based on a drying slag component with granulation up to 1.0 mm in an amount of 5 to 20 % by weight and/or a component from a magnetic fraction from desulphurization slag with granulation up to 2.0 mm in an amount of 5 to 30 % by weight , mixed with at least one component which is a fine-grained dry or wet iron-bearing waste product and selected from such ferrous waste waste: blast furnace waste dust from the dedusting of gases from iron or steel smelting furnaces whose granulation does not exceed 1.0 mm in an amount of 2 % to 30 % by weight; waste drying slag with a granulation of up to 1.0 mm in an amount of 5 % to 20 % by weight; waste sludge iron-bearing fraction from metallurgical processes from Dąbrowa Górnicza with granulation up to 1.0 mm and/or waste sludge iron-bearing fraction from metallurgical processes from other smelters with granulation up to 1.0 mm in an amount of 5 % to 50 % by weight; waste iron-bearing fraction of ArcerolMittal Poland from Kraków, with granulation up to 1.0 mm in an amount of 15 % to 80 % by weight; waste magnetic fraction from desulphurization slag with granulation up to 2.0 mm in an amount of 5 % to 30 % by weight.

(73) Instytut Ceramiki i Materiałów Budowlanych (PL)