Life-cycle solutions for conveyor installations in the cement industry

Belt conveyor systems in mines, quarries and cement plants operate under the most adverse conditions. The extraction and processing of minerals generate large volumes of extremely abrasive particulates, which can get into machines and contaminate lubricants. This accelerates wear on bearings, seals, gear sprockets, couplings and other rotating parts, and can ultimately result in their failure.

Belt conveyors operate at relative low speeds, but often under heavy loads and in some cases under exposure to elevated temperatures (Figure 1). All this makes enormous demands on bearings, seals and lubrication. Poorly accessible installation locations can also complicate maintenance and condition monitoring. Fouling and inadequate lubrication are responsible for more than 50 % of all bearing failures in such applications.

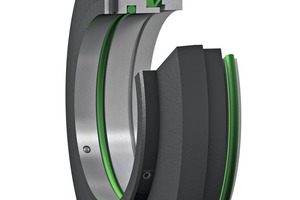

SKF’s range of products for conveyor systems covers the equipment’s entire life-cycle and includes bearings, housings, seals, lubrication systems, servicing/maintenance solutions and reliability engineering. It features, inter alia, highly effective design elements for belt conveyors, such as the SKF “three-barrier solution”, housings, sealed SKF Explorer self-aligning roller bearings and the new SKF Taconite seal (Figure 2).

SKF has developed, in the form of its “three-barrier solution” an equally environmentally friendly and rational-cost concept to extend the service-life of belt-conveyor pulleys and complete systems. Installation of this system means that the belt conveyor bearings have three effective “protective layers” against fouling, reducing the necessary flow of lubricant by up to 90 % compared to “conventional” sealing solutions. This, of course, also cuts maintenance costs noticeably.

SKF also supplies housings consisting of high-quality cast material or, optionally, of ductile cast iron. These have large webs in their lower section and are reinforced at the fixing holes to enable them to better withstand impacts and make them less sensitive to deformations of the lower section and bearing seat under exposure to high stresses. These housings are suitable for installation of sealed SKF Explorer self-aligning roller bearings, manufactured from a recently developed new steel (including a patented heat-treatment process). Explorer bearings are prelubricated ex-works and feature integrated seals to protect the internal bearing components. This improves wear-resistance and sealing, with the result that, even with inadequate lubrication and in dirty environments, these bearings have service-lives of up to three times as long as standard types.

SKF’s “three-barrier solution” can be combined with the new SKF Taconite seal for service in extremely dirty conditions. This combination assures best possible sealing of the housing interior - against both fouling and external cleaning operations.

SKF includes its Idler Sound Monitor Kit in its range specifically for servicing and maintenance purposes (Figure 3). This portable tool permits the detection of initial indications of idler failure at an early stage, thus minimising belt damage and helping to achieve lower-cost maintenance scheduling.