Limestone requirements for high-limestone cements

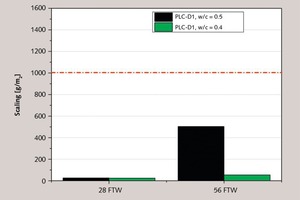

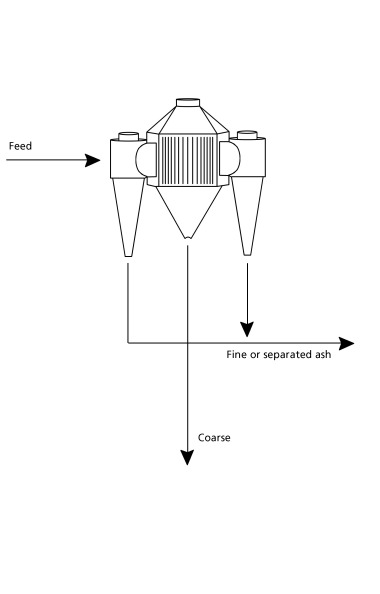

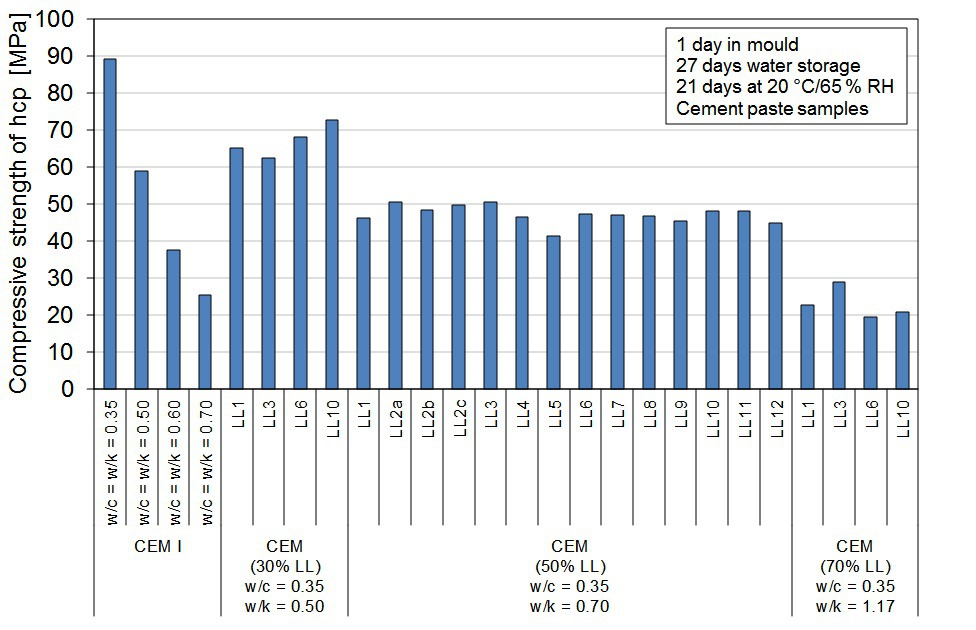

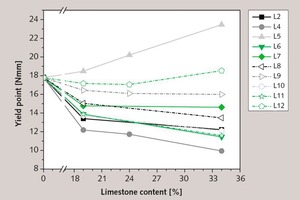

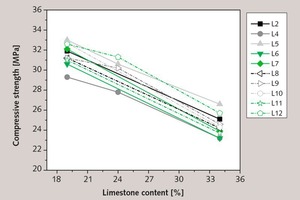

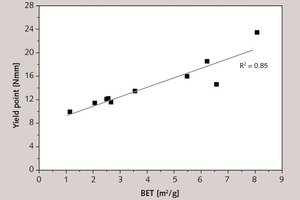

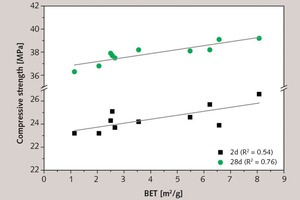

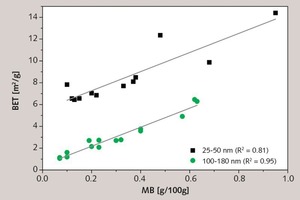

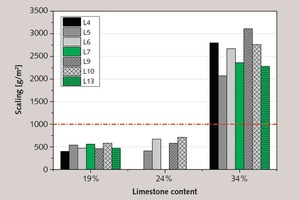

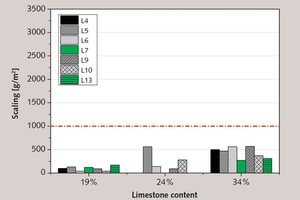

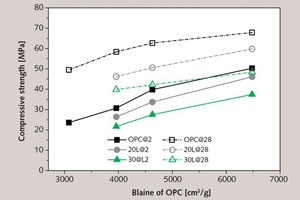

Tests performed on mortars permit the conclusion that, within the scope examined here, neither chemical composition nor mineral-phase type and content have significant effects on workability, 2-, 7- and 28-day cement compressive strength and durability. The tests described here were performed on blended cements containing 19%, 24% and 34% ground limestone by mass, and demonstrate the importance of the fineness of the limestone and clinker particles for cement properties and concrete durability. If the differences in the granulometric parameters of the limestones are excluded, not only limestone content but also BET surface area are critical for the cements’ subsequent working properties. Tests on concrete in the laboratory indicated that, apart from the cement’s limestone content, only the w/c-ratio is definitive for the durability of concretes. Even concretes based on blended CEM II/B cements (using CEM I 52.5 R as the initial cement) containing 24 % limestone by mass exhibited high internal and external frost resistance (CDF/CIF and cube test).

1 Introduction

Among endeavours for reduction of climate-relevant CO2 emissions in the cement industry, particular importance is attached to the replacement of Portland cement clinker by other main constituents. Around the globe, only fly ash and ground granulated blast furnace slag (GGBFS) are currently available in significant quantities. Both of these materials are by-products, and are subject to significant cyclical economic and seasonal fluctuations, unlike limestone, which is available in adequate quantities at numerous locations.

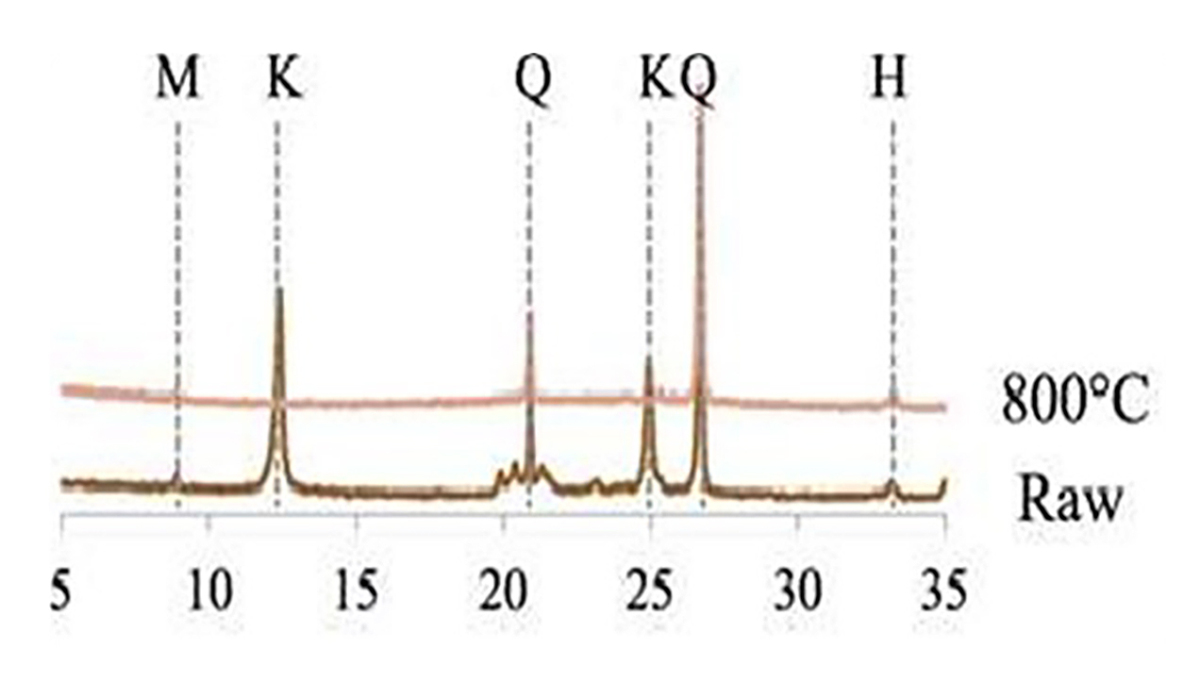

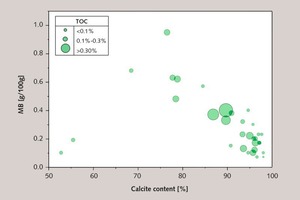

Natural occurring limestone is a non-homogeneous mixture of...

![10 Calculated phase volume for Portland limestone cement as a function of limestone content;Cc – CalciteCH – PortlanditeEt – EttringiteM$ - MonosulfoaluminateHc – HemicarboaluminateMc – MonocarboaluminateHt – HydrotalciteFe-H – Iron-containing hydrogarnetPor – PorosityA description of the modelling concept is provided in [3]](/uploads/images/2016/w300_h200_x400_y395_101550373_5732934c10.jpg)