Improving early-age strength of fly ash cement and increasing fly ash content by inter-grinding

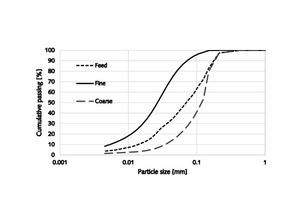

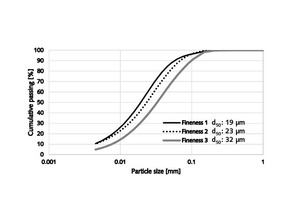

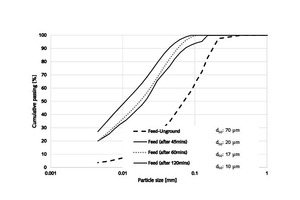

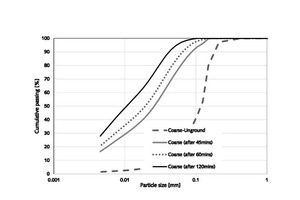

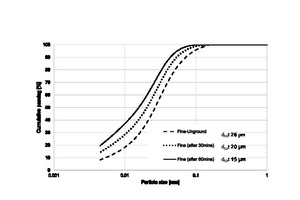

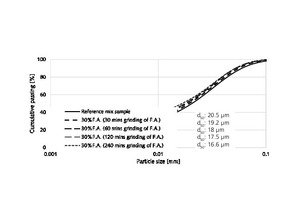

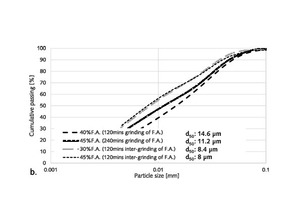

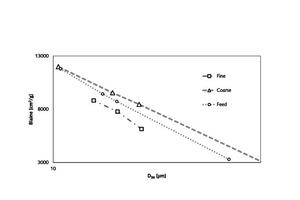

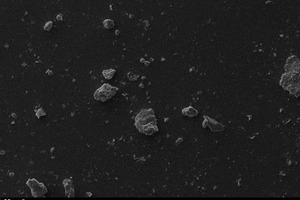

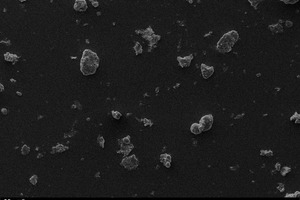

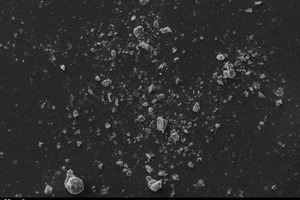

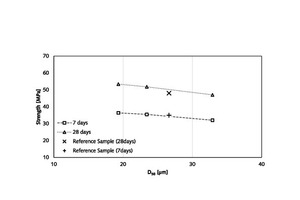

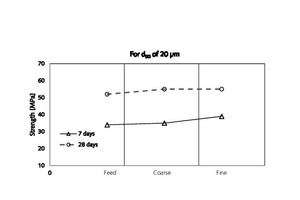

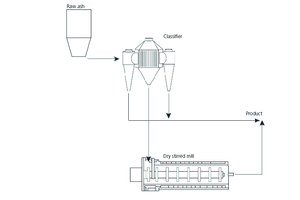

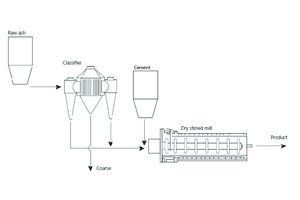

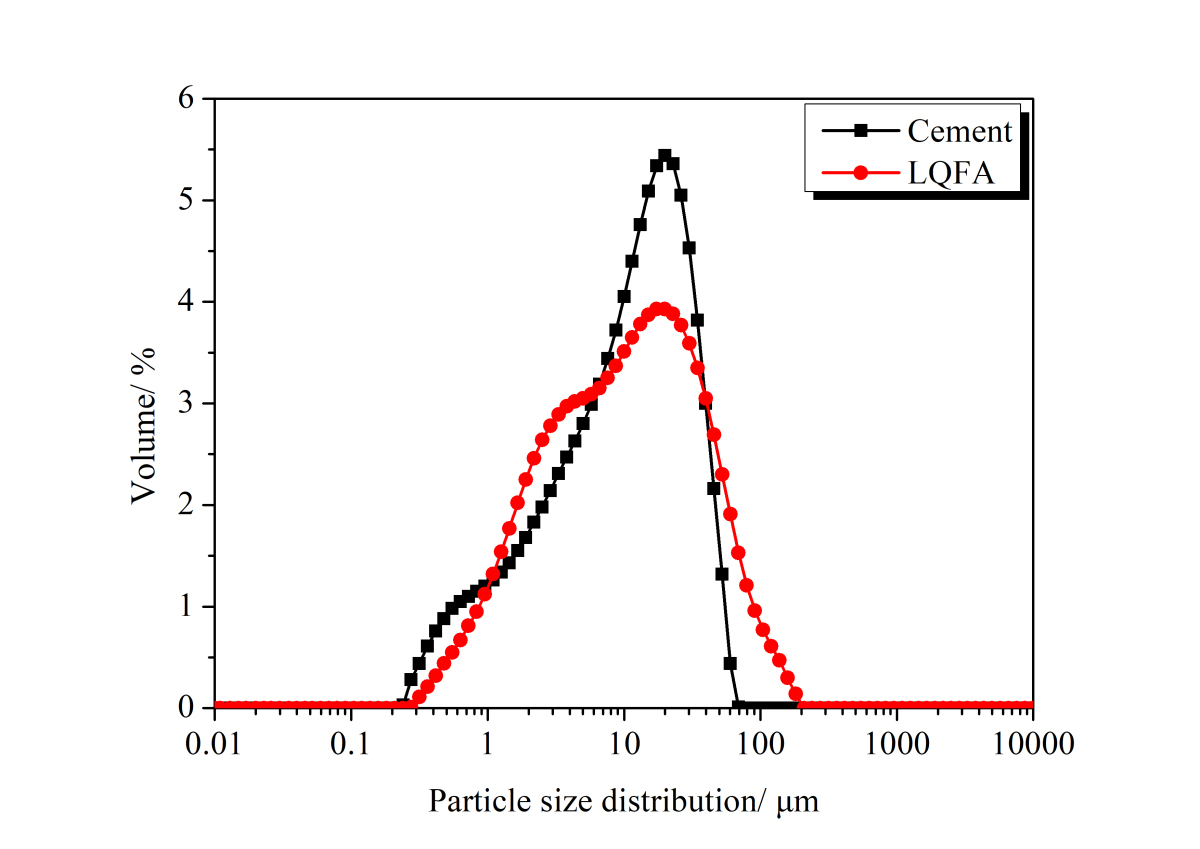

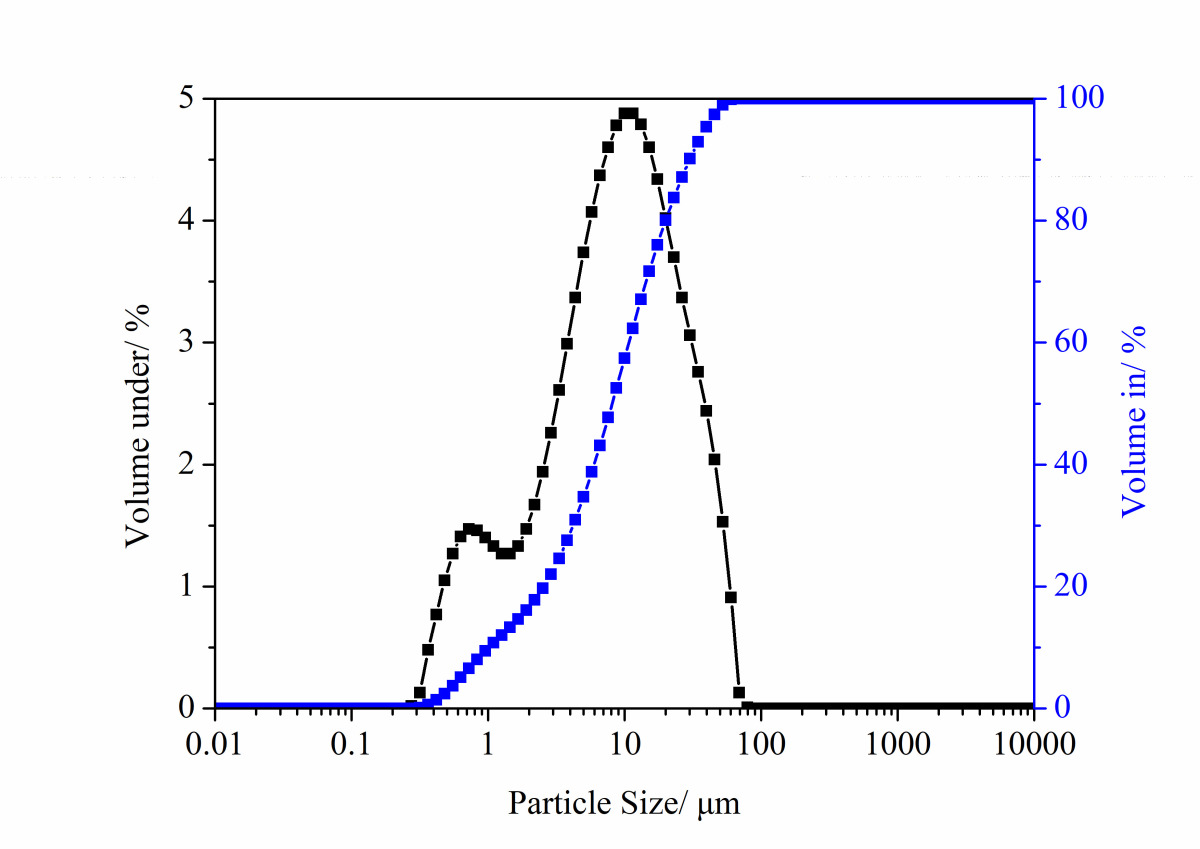

Thermal power plants have a significant role in energy production. Within the combustion process, a by-product called fly ash is obtained and can be utilized by the cement industry as an additive for improving the overall economy of the manufacturing process. This study focuses on evaluating the performance of a fly ash classification plant with regard to quality development in the streams of material through the classifier. Within that scope, the cementitious properties of raw, fine and coarse ash were determined in dependence on changes in their degree of fineness. The values of fineness were adjusted both by changing the operating conditions of the classifier and by way of laboratory-scale grinding tests in which inter-grinding of cement and fly ash was taken into consideration. The study showed that the streams of material through the classifier had similar quality results, and that inter-grinding could increase the ash content by up to 45 % with 14 % improvement in strength. Moreover, it proved possible to nullify the negative effect of fly ash addition on early-age strength of fly ash cement mixture by means of inter-grinding.

1 Introduction

Fly ash is a by-product of coal-fired power plants. In Turkey, around 650 000 t of fly ash is produced annually, requiring around 60 000 m2 of land area for storage [1]. Depending on the lifetime of the power plants and the utilization rate of the fly ash, this area can be even larger.

The cement manufacturing process is known as energy intensive. The total energy consumption of the cement production process varies between 110 kWh/t and 150 kWh/t, roughly 60 % of which is utilized for grinding the raw material and cement clinker. Therefore, cement producers aim to utilize...