Major German cement producer with new job for Intercem

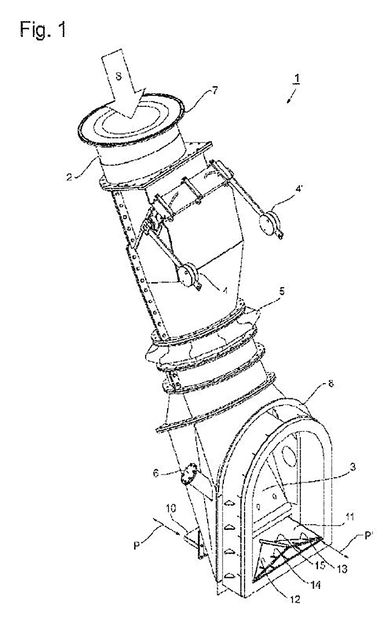

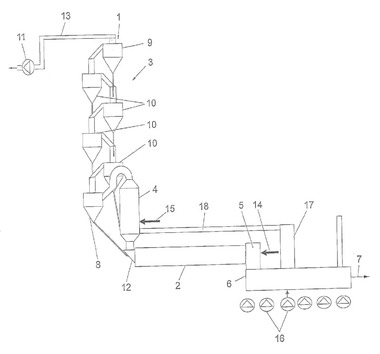

Intercem has been commissioned to optimize the raw meal dosing process at a major German cement plant. At the moment, raw meal dosing for one of the company’s kilns takes place upstream of the bucket elevator that serves the heat exchanger building. Downstream of the bucket elevator, the volume flow of material is divided up between the two heat changer sections by an air-slide system. A pair of rotary valves seal off the heat exchanger at both ends.

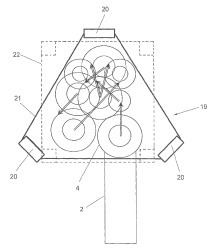

The existing dosing system is supposed to remain in service for implementing the maximum flow rate. Downstream of the bucket elevator, an adjustable splitter divides the flow of material. Air slides feed the material into two dosing hoppers. From there, each heat-exchanger section receives its own separate supply of raw meal via gravimetric mass-flow proportioners. Finally, the raw meal is forwarded to the loading station on a short pneumatic conveyor.

Intercem has taken on this contract order for a 3D-scanner-based quantity survey of the relevant section of the heat exchanger building, plus the supply, installation and commissioning of the processing equipment. The job’s special challenge is to plan the insertion and – considering the building’s headroom – to install the equipment without the help of a crane.

//www.intercem.de" target="_blank" >www.intercem.de:www.intercem.de