Method for controlling ammonia content in cement flue gas and cement plant with controlled ammonia emission

(22) 14.09.2017

(43) 29.03.2018

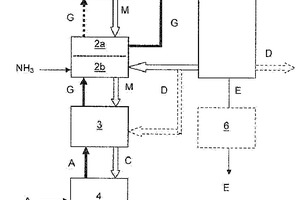

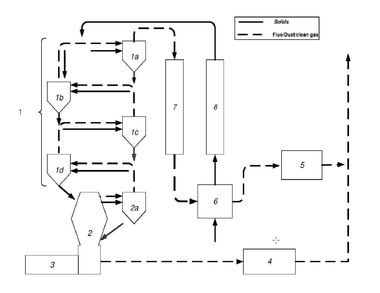

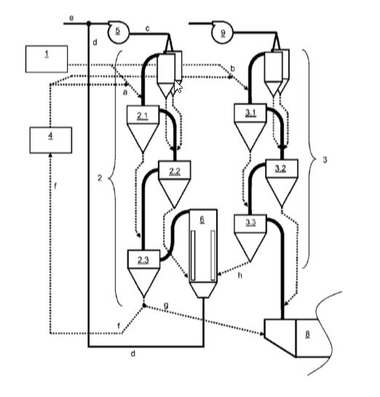

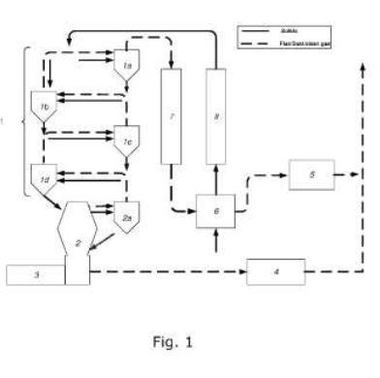

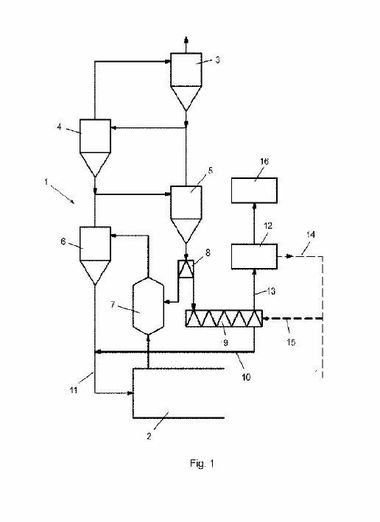

(57) The invention relates to a method for controlling an ammonia content in the exhaust gas (E) from a cement manufacturing plant wherein the gaseous stream (G) produced during sintering a raw meal (M) to form a cement clinker (C) is passed into a conditioning stage in which an amount of SO2 is adjusted that suffices for reducing the ammonia to the desired level by reaction of ammonia with SO2 to form ammonium sulfur compounds which are captured in a dedusting filter of the plant as solid material. The invention further provides a cement manufacturing plant comprising a raw material mill (1) for grinding a raw material to provide a raw meal, a preheater (2a) or a preheater/calciner (2) for preheating or preheating and calcining the raw meal, a kiln (3) for sintering the raw meal to a clinker, a cooler (4) for cooling the clinker and a dedusting filter for separating a gaseous stream from the preheater and/or the raw material mill into a solid dust and an exhaust gas, wherein a conditioning unit (5) receiving an adjusted amount of SO2 and equipped with a device for measuring the content of ammonia and SO2 in the gaseous stream from the preheater and/or the raw material mill is arranged before the dedusting filter or made integral with the dedusting filter.

(71) HeidelbergCement AG, Berliner Str. 6, 69120 Heidelberg (DE)

(84) ARIPO (BW, GH, GM, KE, LR, LS, MW, MZ, NA, RW, SD, SL, ST, SZ, TZ, UG, ZM, ZW), Eurasian (AM, AZ, BY, KG, KZ, RU, TJ, TM), European (AL, AT, BE, BG, CH, CY, CZ, DE, DK, EE, ES, FI, FR, GB, GR, HR, HU, IE, IS, IT, LT, LU, LV, MC, MK, MT, NL, NO, PL, PT, RO, RS, SE, SI, SK, SM, TR), OAPI (BF, BJ, CF, CG, CI, CM, GA, GN, GQ, GW, KM, ML, MR, NE, SN, TD, TG)