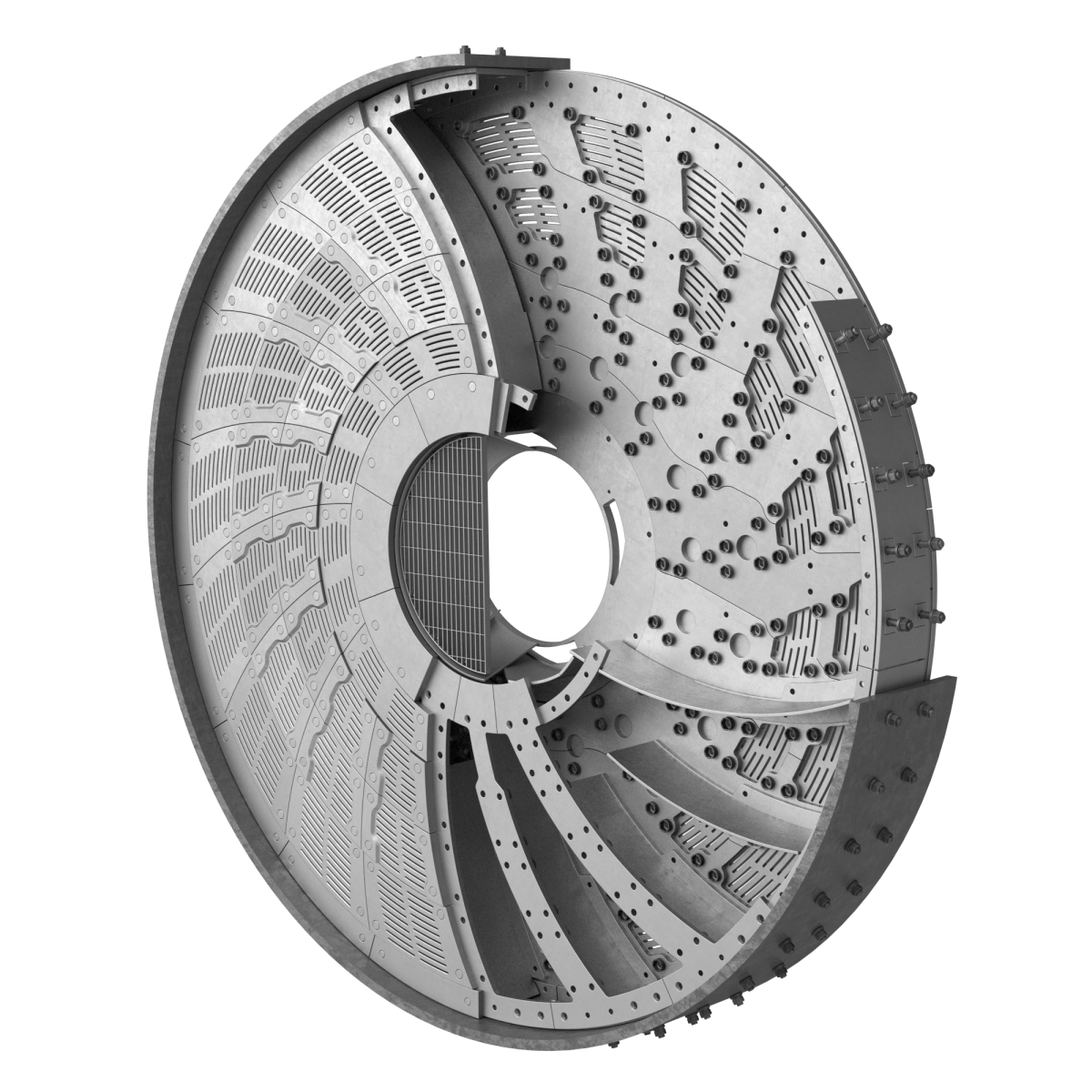

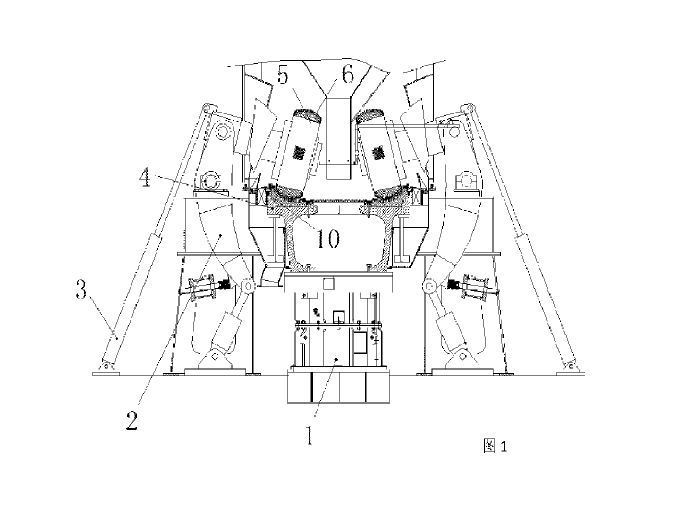

Method for grinding of material, especially raw material for clinker calcination, in mills, particularly in ball mills

(22) 23.10.2019

(43) 28.04.2021

(57) A method of grinding material, in particular a raw material mixture for firing clinker in mills, in particular ball mills, in a tubular ball mill with or without discharge and/or in a vertical mill, in circulation and/or in a grinding circuit by separating fine gravel, so-called semolina remaining after grinding the feed material with subsequent introduction into the dry and wet grinding process, in which the grinding time of the material is reduced by 40 to 80%.

(71) Lörke, Paul (DE); Martauz, Pavel (SK)