Method for manufacturing milk of lime using waste heat recovery line

(22) 05.09.2017

(43) 26.02.2018

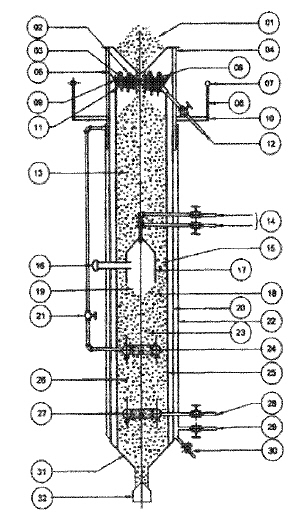

(57) The present invention relates to a waste heat recovery line capable of recovering waste heat generated in the production of liquid limestone oil and transferring the waste heat to water to supply water at an optimum temperature necessary for hydration reaction to shorten the production time of the lime oil while increasing the reaction efficiency. The present invention relates to a method for producing lime oil, which comprises: a water storage step of receiving water at room temperature from a water supply pipe and storing the water at a room temperature in the water tank; and a water storage tank for storing water stored in the water tank from one end of the water supply pipe connected to the water tank; a raw material charging step of transferring the quicklime powder from one end of the raw material input pipe to the other end through pressure supply from a BCT vehicle to which fresh lime powder is transported; after the water is supplied, the raw liquor is poured from the other end of the raw material charging pipe; a lime oil producing step of supplying lime oil to the lime oil tank and supplying lime oil to the lime oil tank, wherein the lime oil is supplied to the lime oil tank through an agitator installed in the lime oil tank; a waste heat recovery step of circulating the waste water through a waste heat recovery line so as to be stored in the water tank after heat exchange with the lime oil stored in the waste water tank; and a lime oil discharge step of discharging the lime oil through a discharge pipe installed at one side of the lime oil tank.