Modernization at the HeidelbergCement plant in Ennigerloh

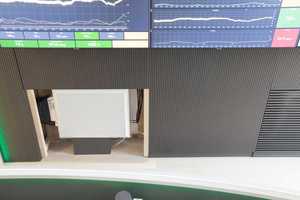

A keen eye to quality: new production control center with flexible-use large-screen wall makes it easier to precisely monitor systems and manufacturing processes. Newly developed suspended ceiling panel with HCL illumination supports improved employee concentration and performance.

At the HeidelbergCement plant in Ennigerloh, raw materials including limestone, clay and marl are sintered in the rotary furnace system to create cement clinker, which is then pulverized to form cement as the end product. A control center which comprehensively monitors all system components and manufacturing processes ensures consistently high product quality in this process. However, as the equipment fulfilling this function was showing its age, the company decided in favor of a full redesign. The replacement facility set up by Jungmann Systemtechnik GmbH & Co. KG (JST) now consists of a highly advanced control room containing two ergonomic workstations and flexible-use technology. There is also a proactive large-screen wall that offers the opportunity for team-view usage, among other options. The use of multi-consoling for control room management enables a range of situation-dependent systems, production data or cameras to be accessed on the large-screen wall as well as on the individual workstation monitors. This also means the 32 screens in the old control room have now been reduced to 16. The sound-absorbing OPAL-X11 suspended ceiling panel has been developed specifically for control room shift operation, and features an integrated HCL light source which additionally promotes operator concentration and performance. The overall setup and JST’s hardware and software ensure a pleasant work environment as well as faster incident response times.

Cement has been produced at the Ennigerloh HeidelbergCement site since right back in 1909. To manufacture it, first lime marl from the company’s own quarries is batched together with high-percentage limestone material from the Sauerland region as crushed stone, or fed to the raw mill. In the raw mill, the broken-up material is dried by the furnace gases, finely ground, and then temporarily stored in silos for homogenization. Then, during combustion in the rotary furnace at a temperature of around 1450 °C, a sintering process creates cement clinker, from which cement is eventually obtained in further grinding processes. Precise monitoring of sophisticated manufacturing steps is provided by a production control center with two workstations. This ensures a consistently high quality in the end product.

By mid-2020, this essential task was performed from premises with a setup and technical equipment that were somewhat outdated. It included a total of 24 individual monitors with rigid, inflexible displays, as well as a high number of keyboards and mice, on a control room console that was around eight meters in length. Four generations of control technology coexisted there. “With so much hardware in place, retaining an overview was a challenge for staff there,” comments Volker Weimer, responsible for the HeidelbergCement project at JST. “For example, if an operator input something on a computer at the far left of the console, and then needed to check something on the monitor at the right-hand end, they had to roll along the entire table. Of course that had an impact on response times.” Having all 32 screens in view was a significant challenge for a control center operator who is usually working alone. “The control functions were very time-consuming for employees,” Heinz Bröker, Plant Manager for the Ennigerloh cement plant confirms. So the management at HeidelbergCement decided to set up a modern, ergonomic control room which would be planned to facilitate a significantly better overview of all processes.

A large-screen system with team-view option makes monitoring easier

For planning and implementation of this project, Jungmann Systemtechnik GmbH & Co. KG was commissioned with designing a prestigious production control center with two workstations, the equipment in which would enable a single employee to operate and monitor the entire plant without difficulty. The newly installed large-screen system is a key element of this, as it enables the associated special hardware and software to be precisely and flexibly controlled: multi-consoling means that monitors can be correlated in such a way that the operator can always switch to the display they currently need on their own workstation screens or on the large-screen wall. Overall, this significantly reduces the number of monitors needed in the Ennigerloh cement plant production control room. “Both workstations are equipped with multi-consoles consisting of only four screens, and each workstation has one keyboard and a mouse,” Weimer explains. “The large-screen wall includes six displays with very narrow frames that can be used for team-view purposes. Thanks to the MouseHopping multi-consoling function, these can also be operated using the mouse-keyboard unit on the console.” This makes it possible to switch to all sources required for a complete overview, either on the DisplayWall or on the workstations. The required displays are rapidly relocated and processed according to immediate need.

Situation-specific adjustments can be made in seconds using the CommandPad, a touch display integrated directly into the operator console. The pad is equipped with an interactive myGUI user interface, which reflects a 3D layout for the entire control room infrastructure. All the necessary sources are shown on the left-hand side, and these can be easily dragged to the workplace monitors or the DisplayWall by means of customizable icons, and then operated there. This enables reliable control especially in stressful situations. “When a fault occurs, operators must be able to quickly find the relevant camera and/or system images so they can remedy the problem,” explains Weimer. What are referred to as myActions can also be used for this; these are pre-defined scenarios stored in myGUI which can be accessed with just a single touch in the CommandPad. Together with the intuitive operating concept this functionality shortens employee response time, for example in the event of temperature limits being exceeded in the rotary furnace, and in this way facilitates compliance with the high quality standards at HeidelbergCement.

Air conditioning, light and acoustics concept based on the DisplayWall and suspended ceiling panel

To create pleasant working conditions for plant operators, a sophisticated air conditioning, light and acoustics concept has been implemented in the control room, in which the large-screen wall once again plays a central role. “As well as being designed using acoustically dampening materials, the DisplayWall also integrates air-conditioning functions,” explains Weimer. Cool air flows into the control room through ventilation grilles below the displays, rises diagonally, and cools the room; it is then silently suctioned out above the kitchenette installed on the rear wall of the control room. At 50 by 50 cm each, the air outlets in the DisplayWall are particularly large, making it possible for the entire air volume of the room to be replaced at a very low flow speed. This prevents draughts that could impact operator comfort. The employees are also shielded by the ergonomic, height-adjustable control room consoles, which go down to ground level. “The new air-conditioning concept is certainly impressive,” Bröker comments.

There are also two OPAL-X11 acoustic suspended ceiling panels installed in the new production control center. The shape and installation of these are precisely adapted to the semi-circular consoles below them. This solution, newly designed by JST in collaboration with experts in room acoustics and light design, consists of material with an aw value of 0.8. “That means that around 80 % of the speech sound located beneath it is absorbed by the suspended ceiling panel,” explains JST Consultant Dirk Lüders, who supported the development of the panels. “The result is reduced reverberation time and therefore better acoustics at this workstation.” In addition, the ceiling panel has been equipped with Human-Centric Lighting (HCL) that enables the emitted color value to be changed between cold and warm white. This means the system can recreate the color progression of daylight, supporting operator concentration and performance, for example during night shifts. The light color can be directly adjusted to suit individual needs using the CommandPad on the console.

Integrated AlarmLight and audio system

In addition, the AlarmLight can be integrated into the suspended ceiling panel. The special illumination for control console workstations and the large-screen wall can be controlled from the monitoring system, and can flash or change color when an error message is incoming. The suspended ceiling panel has also been combined with an audio system that enables targeted sound emission above the operator and can support the AlarmLight by means of an acoustic signal. The result is that incoming alarms are never missed, even if the employee is not currently at their workstation. “The suspended ceiling panels are not just visually attractive, but also create a perfect atmosphere in the room, with glare-free light and optimum acoustics,” says Bröker, talking about this innovation.

The new production control room in Ennigerloh has been in use since August 2020. The client is very satisfied with how the project went, and the advanced equipment: “With JST’s technology we were finally able to bundle all control technology tasks and therefore to enable the transition to a relaxed work environment,” Bröker said, summarizing the process.

www.heidelbergcement.com | www.jungmann.de