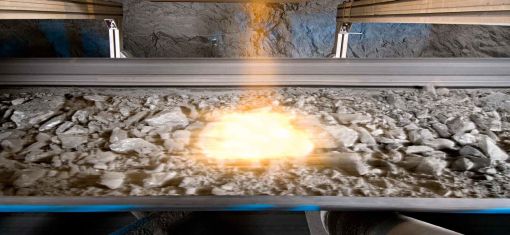

Quality assurance and process control in modern cement plants

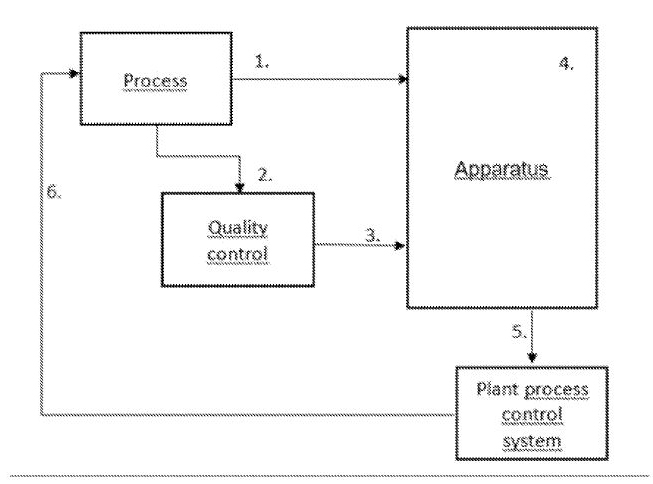

Modern analytical methods are meanwhile standard in the cement industry for use in quality and production control.

Assurance of quality and performance

The functions of a modern plant laboratory are numerous and diverse, must be completed promptly, and exceed the scope of testing required by the applicable standards. In addition to the obviously necessary assurance of the conformity of the products to the relevant...