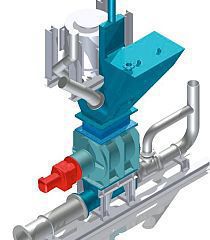

Müllerkalk opts for pneumatic conveyance with ceramic rotary valves

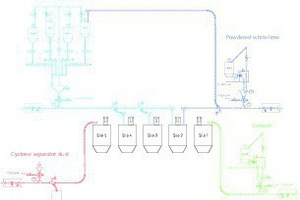

The operators of the Müllerkalk and Wotan cement plants have decided in favour of four pneumatic conveying systems by bulk handling equipment manufacturer Kreisel. This article describes the project from its first planning phase through its final implementation.

1 Introduction

Portland cement producer Wotan Zement and lime supplier Müllerkalk are both medium-range, fami-ly-owned enterprises located in Üxheim-Ahütte, in the Volcanic Eifel region. Their products are derived from limestone found in the Hillesheim limestone hollow.

Müllerkalk makes burnt and unburnt lime products and unburnt dolomite products and markets fired items such as powdered white lime, quick lime, lump lime and white lime hydrate. The Wotan Portland cement plant, in turn, makes about nine kinds of cement, all available as bag or bulk goods.

At the company’s new mixing plant...