New ECS/ProcessExpert 8.3 for cement and minerals industries

The new FLSmidth ECS/ProcessExpert 8.3 is the latest version of the FLSmidth advanced process control solution, which improves on a number of features and benefits, including easier transitions for cement recipes.

Having been installed and tested in four sites, it is now available for different cement and mineral plant applications, including as a free commercial release to all existing ECS/ProcessExpert V8.x customers.

FLSmidth’s Global Product Line Manager for Process Optimisation, King Becerra, said the updated ECS/

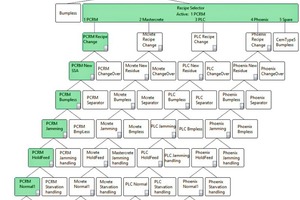

ProcessExpert had unprecedented advanced techniques that helped stabilise the plant, optimise production, manage and correct process disruptions and minimise wear on plant equipment – all to ensure highly efficient and optimum plant performance: “Some of the advanced techniques used by the new system include model predictive control and fuzzy logic rules. These allow it to continuously monitor the plant’s process and quality parameters and continuously compute new control set points with more speed and accuracy than a human operator. Among the new features, we can emphasise the ability to add recipes on the fly. In the past, adding a new cement recipe required a considerable amount of time to adjust the advanced process control strategy. Now, we have included the ability to easily configure how a new recipe should be handled. There is also a full decision tree on the front page of the system giving operators a better understanding of the controller actions – the decision tree can even provide verbal explanations of the actions. Additionally, newly enhanced full plots on the front page mean that operators can now easily see all actuator actions and all measurement responses to that given action from the main page, allowing for a more complete understanding of what the active controller is doing. Overall, it provides operators with a clearer indication of the reasons behind the decisions being made, building on their confidence in the system.”

ECS/ProcessExpert 8.3 is designed with long term utilisation in mind to maximise benefits for customers. To ensure this, FLSmidth has added proactive PlantLine Service Agreements, including remote monitoring of key performance indicators, as an integral part of the system package.

Mr. Becerra said the close relationship between customers and the

FLSmidth development team enabled such continuous innovation and was essential to maintain FLSmidth’s competitive edge.

To find out more about ECS/ProcessExpert 8.3, or other FLSmidth process and quality control solutions, visit

//www.flsmidth.com/automation" target="_blank" >www.flsmidth.com/automation:www.flsmidth.com/automation