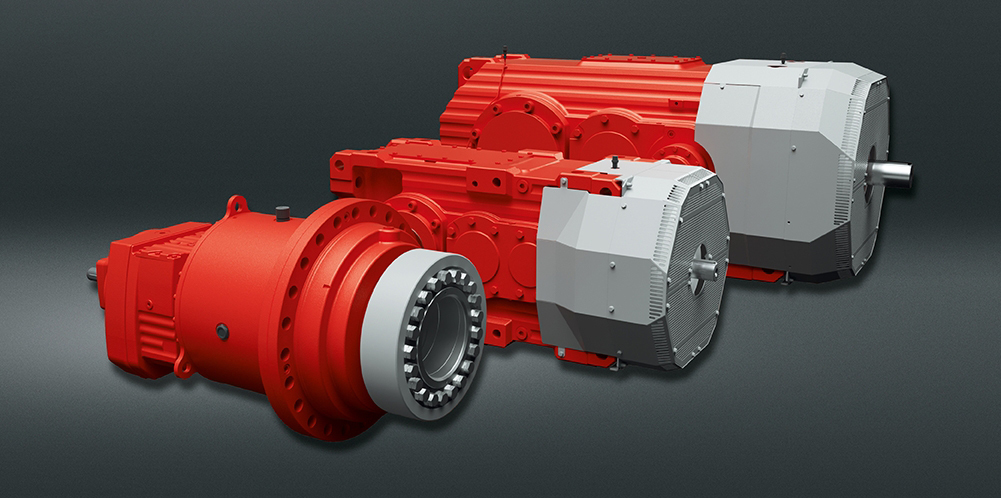

New mechatronic industrial gear unit

In many industrial sectors, the criteria to be met by conveying systems are becoming more demanding and specific and may even require appropriate documentation. The mechatronic industrial gear unit developed by SEW-Eurodrive constitutes an intelligent drive system for conveying and handling applications. It lets the user simultaneously monitor, evaluate and directly intervene in the status of both the drive itself and the process it serves. Now, innovations can be implemented under a whole new set of perspectives, because the employed motor and inverter technology makes it much easier to adapt to different tasks and local conditions. With this technology, aspects like high breakaway and acceleration torques resulting from prolonged periods of non-use are just as easy to manage as soft start-up curves.

Even at the early design stage, emphasis was placed on maintaining a holistic approach. The mechatronic industrial gear unit features impressive system efficiency that helps reduce energy costs. Well-integrated, mutually attuned drive components make for long life cycles and high plant availability. Thanks to integrated motor technology, this kind of drive offers higher output per size, with correspondingly smaller dimensions and lower system weight.

Above all, however, the mechatronic drive system helps optimize production processes. For example, it has already been proven in practice that load-dependent belt speed control saves some 16–20 % electricity [1]. Being able to optimize processes not only increases productivity, but is also helpful for ironing out vague points of design and reacting to after-the-fact changes in service criteria.

The mechatronic drive system makes it easy for the user to profit from the numerous benefits of inverter technology. The systematic use of inverter-controlled drives opens up new potentials for belt drives, and easy-to-use software facilitates their implementation. Then, going forward, system functionality is easy to expand and improve simply by adding on new software modules – much like collecting apps on a smartphone.

Characteristics of the mechatronic

industrial gear unit

Compact design, with all components integrated in a mechatronic drive unit

Simplified system planning and design via familiar dimensions and preconfigured solutions with a single delivery time and a single price

Optimized, application-specific accommodation of the drive technology with modular components

High system efficiency thanks to optimally harmonized individual components

High reliability thanks to systems engineering

Lower energy consumption thanks to high efficiency

Less installation cost and effort for the user

High protection class

One face to the customer for the entire system

Thus, the mechatronic industrial gear unit reduces the overall cost of the conveying system, including its cost of operation. Instead of dealing with a number of different technologies and their respective suppliers, users of a mechatronic industrial gear unit get all the necessary technology from a single source, and SEW-Eurodrive takes care of all the project planning, configuration, optimization and, if so desired, even the commissioning and maintenance of the drive solution – an all-in carefree package.

//www.sew.eurodrive.de" target="_blank" >www.sew.eurodrive.de:www.sew.eurodrive.de