New rotary kiln enables simple dismounting and changing of the heating tube

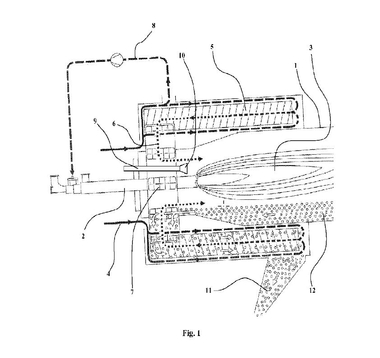

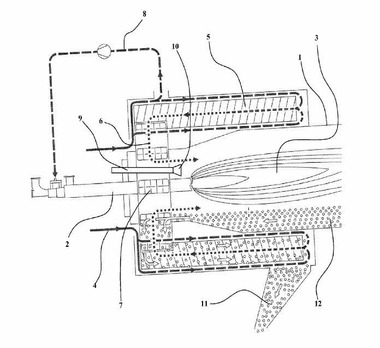

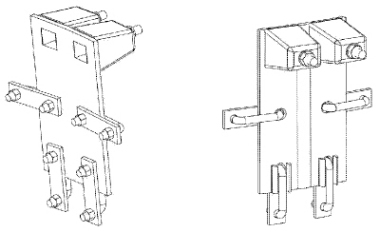

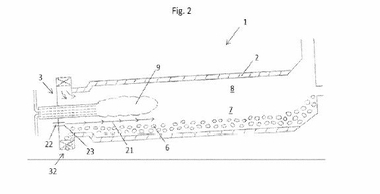

Carbolite from Hope/UK has released a new foldable tubular rotary kiln for laboratory work. It can be used for the continuous thermal processing of small quantities (approx. 1–10 l) of powdery or granulate material – also allowing the use of inert gas – (e.g. calcination). The foldable 3-zone tubular kiln RHZS 12/86/900 provides a maximum operating temperature of 1150 °C and is based on the well-proven HZS 12/900 model. The three zones have a total thermal processing length of 900 mm. The frame of the kiln can be positioned horizontally or at an inclination of up 10°. The variable inclination and rotation speed result in a highly flexible rmaterial retention time. Heating elements in a high-quality vacuum-formed insulation ensure rapid heating-up, outstanding temperature homogeneity and short cooling-down times.

Working with the RHZS is operator-friendly and safe. With this foldable tubular kiln, the dismounting and changing of the heating tube is very simple, which also greatly facilitates the cleaning. When the kilnis opened, a safety switch automatically interrupts rotationof the tube and cuts off the power supply to the heating elements.

The sample material is automatically supplied to the kiln via a Retsch vibratory trough feeder, and is collected in a 5-litre container after the thermal processing.

Advantages at a glance:

1150 °C maximum operating temperature

Heated length of 900 mm

3-zone control

Heating tube with outside diameter of up to 110 mm

Retsch vibratory trough feeder & collection container

Protection gas package available on request

//www.carbolite.com" target="_blank" >www.carbolite.com:www.carbolite.com