Numerical simulation of NOx reduction using low-oxygen combustion and optimization in a TTF precalciner

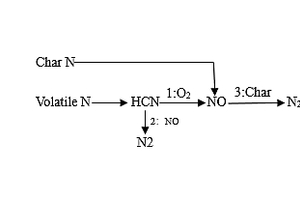

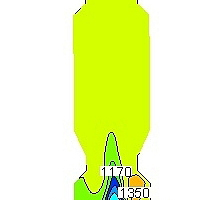

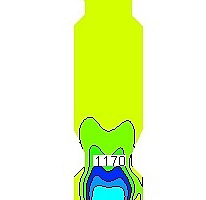

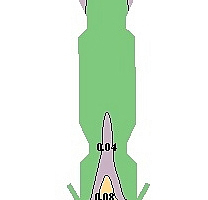

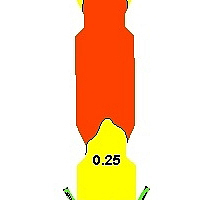

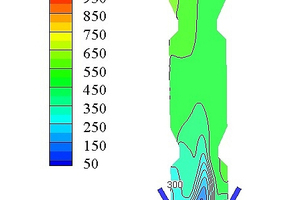

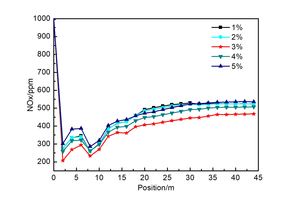

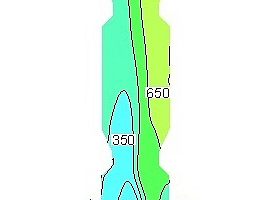

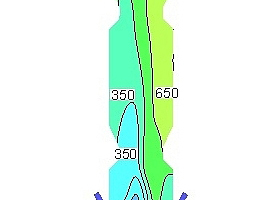

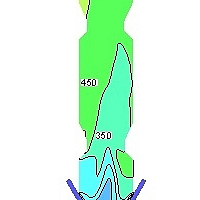

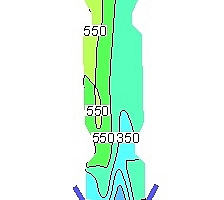

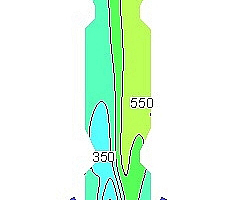

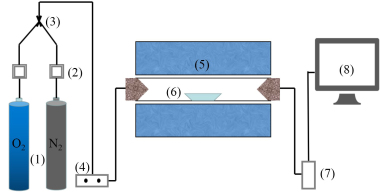

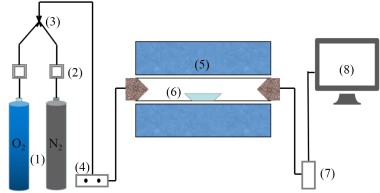

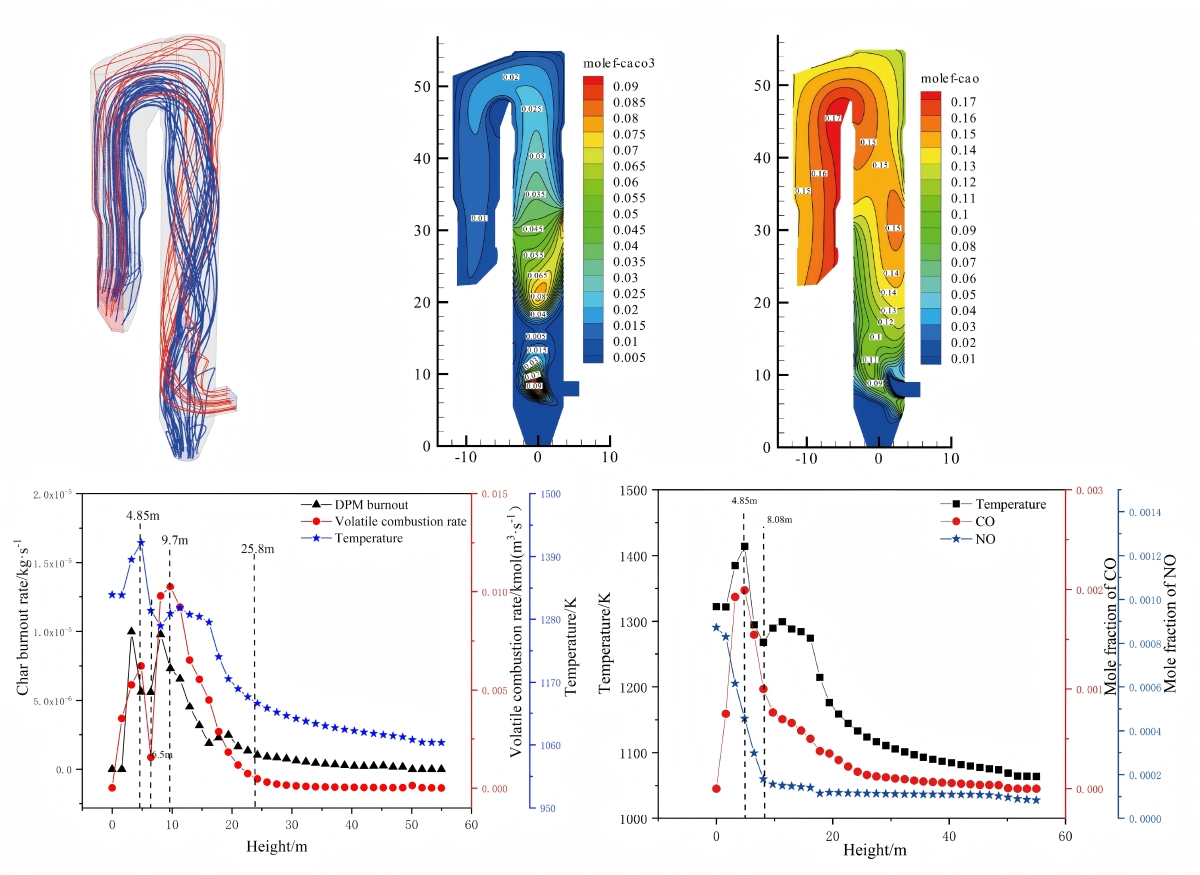

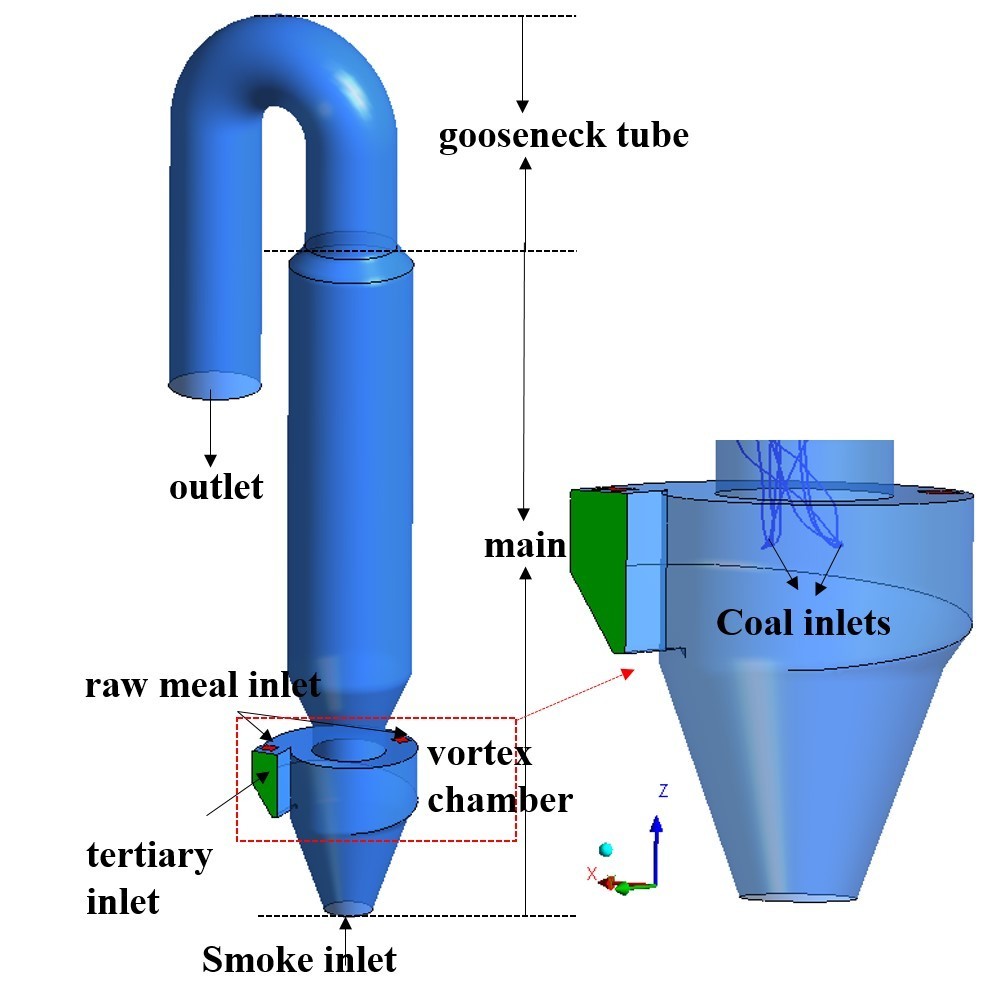

This paper describes the use of low-oxygen combustion technology to reduce NOx emissions in cement production. Numerical simulation was also employed to simulate the pulverized coal combustion, calcium carbonate decomposition and NOx reduction process in the precalciner of a 5000 t/d clinker cement production line. The simulation gave a temperature at the precalciner outlet of 1260 K, a CO2 mass fraction of 28%, an O2 concentration of 1.2% and an NOx concentration of 523 ppm. The data were in good agreement with the actual measurements. The low-oxygen combustion technology was also optimized by changing the oxygen content in the kiln exhaust gas in order to achieve the best conditions. The results showed that the NOx concentration at the outlet of the precalciner would be lowest (468 ppm) when the oxygen content in the kiln exhaust gas was 3%.

1 Introduction

The cement industry is the third largest source of nitrogen oxides after the power industry and motor vehicles, and China‘s cement production accounts for 65% of global cement production. The problem of the resultant pollutant emissions is also a concern for society. The greatest possible reduction of NOx emissions while at the same time ensuring the economic benefits of cement plants has therefore become a major issue. Many scholars at home and abroad have carried out a great deal of research into this problem. Zhao [1] studied the influence of different amounts and locations...