Oxy-calcination process

(22) 30.11.2015

(43) 21.09.2017

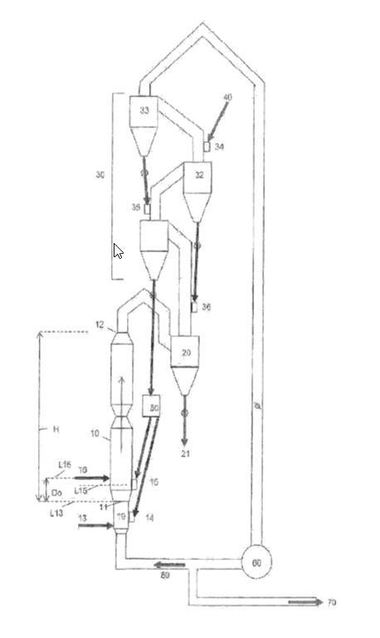

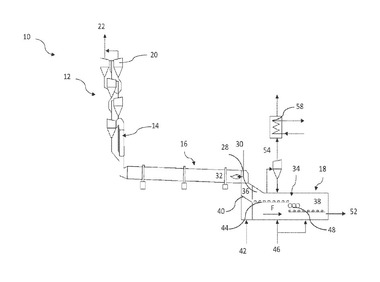

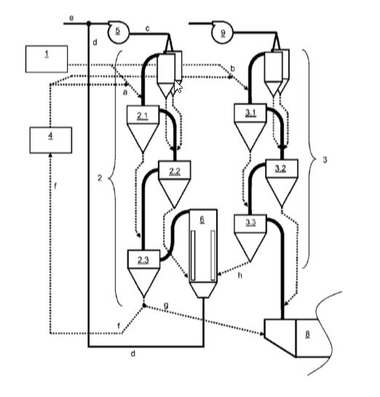

(57) Method and installation for calcining cement raw meal in a calciner whereby fuel and a calciner oxidant having an oxygen content of at least 30 % vol are introduced into the calciner so as to generate either an oxidant-lean zone or a fuel-lean zone in the calciner located between the lowermost fuel inlet level and the lowermost oxidant inlet level of the calciner, between 50 % and 100 % by weight of the raw meal being supplied to the calciner upstream of and/or within the oxidant-lean, respectively the fuel-lean zone.

(71) L‘Air Liquide, Societe Anonyme pour I‘Etude et I‘Exploition des Procedes Georges Claude (FR); Lafarge SA (FR)