PT Anugerah Mortar Abadi from Indonesia builds dry mortar plant with mixing systems and plant engineering from Eirich

PT Anugerah Mortar Abadi is part of the Indonesian Triputra Group. In Wanaherang near Jakarta the company has taken a new dry mortar plant into operation. Here, various types of plaster, mortar, tile adhesive and different colored grout products are manufactured under the brand name Mortindo.

In Indonesia, the market share of industrially mixed dry mortar is around 5 %. Since standards are set to be introduced in the near future, the market share is going to grow rapidly. The aim of Anugerah is to create long-term customer loyalty with high-quality products and excellent service.

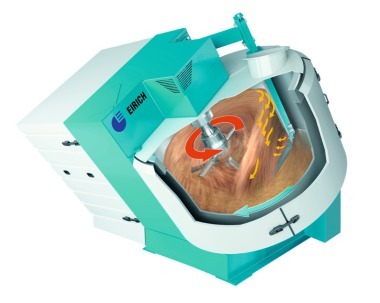

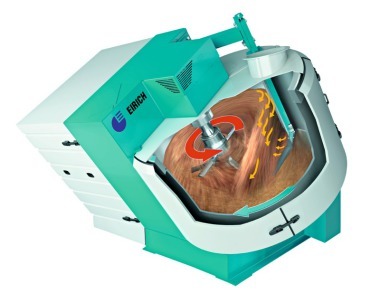

Previously, Anugerah manufactured its products with an older system on the same site, which was supplied by a German manufacturer and featured a single-shaft axial mixer/plowshare mixer. This type of mixer is often sufficient for simple mixing tasks. However, in applications where pigments, fibers or additives down into the ppm range need to be admixed, these mixers reach the system-related limits of their design.

The completely new system – from the feed hopper before the drier to the screening system and the packer and palletizer – was planned and erected by Eirich. The tower system, in which four sand components, four binders and around 20 additives are processed, is designed for up to 120000 t/a in single-shift operation. For PT Anugerah Mortar Abadi, it was important to communicate and work closely with Eirich already during the engineering phase. This meant that all customer preferences and wishes – including good accessibility for maintenance and flexible upgrade capabilities – could be taken into account and implemented.

Components such as driers, screens and packers were procured by Anugerah following the requirements of Eirich, as were the steel structure and silos. Alongside a mixer of type RV19 (1500 l), the Eirich scope of supply included a bucket elevator for transporting the dried sand to the screens, the silo accessories, eight screw feeders, two hopper scales, one additive scale and the control system. The mixer, which is designed for 24 batches per hour, already demonstrated its performance capacity during the start-up phase in the autumn of 2018, delivering excellent homogeneity with up to 30 batches per hour.

The plant concept includes upgrade options to add fully-automated additive feeding and silos for silo-to-truck loading. This investment will enable PT Anugerah Mortar Abadi to maintain and further strengthen its market position in the future.

//www.eirich.com" target="_blank" >www.eirich.com:www.eirich.com