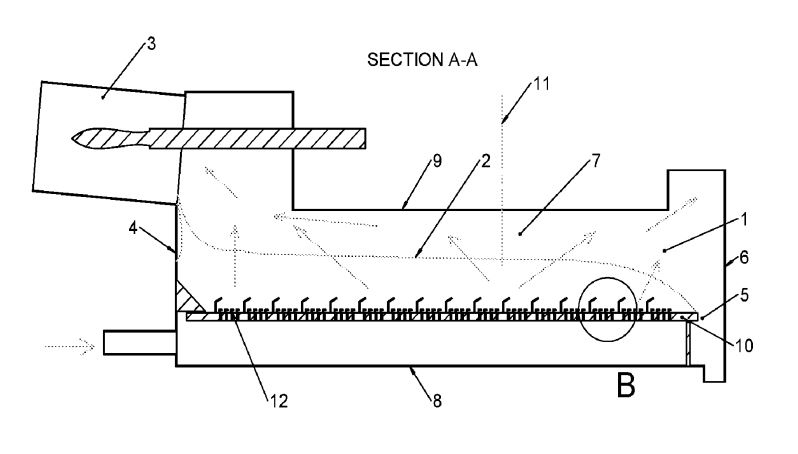

Pakistan cement producer Lucky Cement prefers Fons Technology International (FTI) clinker coolers for its Pezu plant

In June 2016, Lucky Cement ordered two sets of Fons Delta Coolers with 3000 t/d capacity along with two sets of 3-roller clinker crushers for their production lines A & B. Due to the features of FTI clinker coolers and their technology, Lucky Cement has observed that successful results in sustainability are achievable by using Fons Delta Coolers and they can provide a sensible approach in order to reduce energy and fuel consumption and increase productivity. For these reasons and because of the mechanical and maintenance troubles Lucky Cement encountered while using the old clinker cooler and hammer crusher, the company executives decided to make an agreement with FTI to furnish line A & B with new generation unique Fons Delta Coolers. The shipments were to be planned for the end of 2016, the FTI and Lucky teams are curiously looking forward with great interest to seeing the successful results after the commissioning.

//www.fonstechnology.com" target="_blank" >www.fonstechnology.com:www.fonstechnology.com