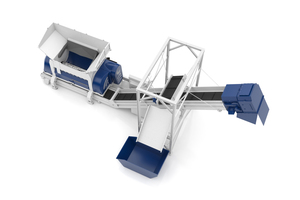

Polaris – one-step shredding

RDF shredding in one go – with only one machine: Lindner presented a new model of the Polaris shredder model at IFAT 2018, the Polaris 1800.

The Polaris was developed for the one-step production of medium-calorific refuse-derived fuel (RDF) which is used for incineration in calciners. The Lindner Polaris shreds municipal solid, commercial and industrial waste to defined final output sizes in one step. Product manager Stefan Scheiflinger-Ehrenwerth: “We have succeeded in establishing the Polaris as a synonym for one-step, cost-efficient RDF processing in the industry. As a leading supplier, Lindner provides the solution for feed materials that contain foreign objects, or are wet and heavy, bulky, or generally difficult – as often encountered in the industry. Polaris is simply ideal for this.“

This very resistance to foreign objects distinguishes all the shredders offered by the Austrian manufacturer, which celebrates its 70th anniversary this year.

Polaris 1800

This smaller model of the series is aimed at companies that still have capacities for materials processing and want to enter the market for medium-calorific RDF. On the other hand, the Polaris 1800 is perfect for those companies in regions that do not have extreme amounts that need to be processed. “Furthermore, the Polaris 1800 also has enormous potential for use in emerging markets that are only just beginning to process waste. Since structures have to be built up there first, this solution is the ideal entry model,” explains Stefan Scheiflinger-Ehrenwerth.

The Lindner Polaris 1800 has an output rate of up to 16 t/h and shreds almost any feed material, in particular, industrial, commercial and municipal solid waste. Polaris users are convinced by the machine’s enormous power thanks to the countershaft drive, flywheel mass effect, optimized material feeding (internal pusher for increased volumes and easy feeding), the hydraulic maintenance door (for fast removal of foreign objects and convenient rotor maintenance) and, last but not least. the robustness and durability of the cutting system’s cutters.

The Polaris series is also equipped with a newly developed cutting system and is – compared to all other single-shaft shredders – the most efficient (€/t). This is confirmed by a study conducted by the Chair of Waste Processing Technology and Waste Management of the University of Leoben/Austria in May 2017. According to the results, Polaris stands for the one-step processing system and is both technically and economically more advanced than competitor machines. The countershaft drive functions like a large flywheel mass acting like a battery. If the Polaris is not fully utilized during operation, the mass charges itself and can therefore absorb load peaks if necessary. This stored energy enables continuous shredding and ensures the highest throughput rates even with difficult materials.