Redesigning raw mix burning behaviour and its impact on kiln productivity

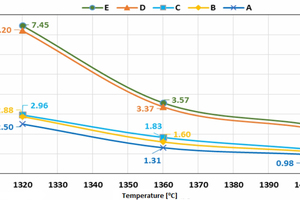

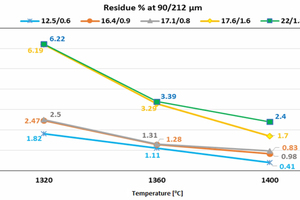

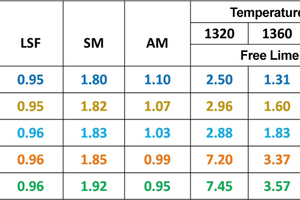

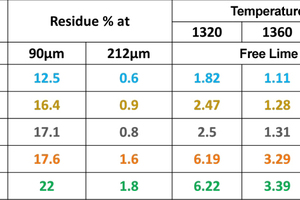

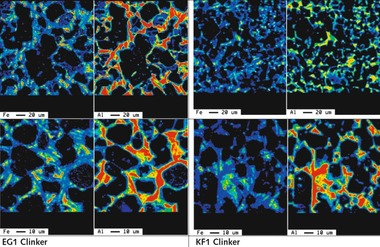

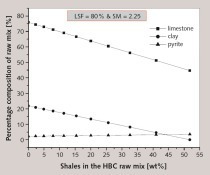

Burnability studies have been carried out to see the effect of different raw materials with different sources and composition on clinkerisation reactions. This burnability study for different raw mixes was done at 1320, 1360, 1400 ºC with retention time of 30 minutes in a high temperature laboratory muffle furnace. The burnability of the raw mix is affected by different factors like difference in limestone grades, its corrective materials, its raw mix ratio proportioning and homogeneity of the raw meal along with its particle size.

1 Objective

Variations in the chemical composition of raw mixes affect kiln operation, refractory line, fuel consumption, clinkerization and finally clinker quality. Clinker is formed through extremely physio-chemical transformations at regular temperature intervals and therefore characterization and evaluation of the raw mix is essential for achieving a suitable design of the raw-mix, smooth operation of the kiln producing better quality of clinker and also increasing the kiln productivity.

The laboratory raw mix burnability study aims at highlighting the reactivity of the raw mix and its...