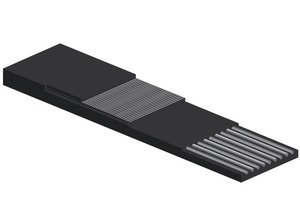

Reinforcement increases service life for heavy work

ContiTech from Hanover/Germany has developed the steel cable conveyor belt STAHLCORD® Barrier for less conveyor belt damage and a long service life in opencast mining. With its new sturdy steel transverse reinforcement in the top cover, the conveyor belt is two to three times more resistant to impact breaks than conventional steel cord conveyor belts without transverse reinforcement. “These properties make the belt ideal for transporting coarse and sharp-edged materials in opencast mining,” Dr. Andrey Minkin, application engineer at the ContiTech Conveyor Belt Group, ⇥points out. The rough working conditions in opencast mining mean high demands on steel cord conveyor belts. Impact breaks occur on the conveyor belts time and again, causing damage to the steel cords in the belts. So-called transverse reinforcements offer more safety and stability.

The STAHLCORD® Barrier is a steel cord conveyor belt with a rubber surface on the top cover, in which thin steel cords run closely together at right angles to the direction of travel of the conveyor belt. They protect the steel cords in the belt carcass and prevent impact breaks and longitudinal slitting in the conveyor belt. Thanks to low reference elongation and the short takeup linked to this, the barrier is ideal for use as an equipment belt in mining machinery or as a short- to medium-length device-related bench conveyor belt, for instance. It is also suitable for working environments where steel cord conveyor belts have to withstand impacts from coarse stone, as is the case with belt conveyors with several feeding points.

“With the STAHLCORD® Barrier, we are now setting new standards,” Dr. Minkin explains. “The increased resistance to impact breaks makes belt slitting practically impossible.” Further advantages of the new steel cord conveyor belt are its outstanding troughability in accordance with ISO 703:2007 and a high ply adhesion in accordance with ISO 15236. The belt is only 5 % heavier than a classic steel cable conveyor belt without transverse reinforcement.

ContiTech used corporate synergy effects for the development of the barrier and the new transverse reinforcement. In that way it meets the high standards required by the automotive sector. “Our customers benefit directly from this development know-how – in the form of long service lives and reliable and low downtime operation of heavy-duty conveyor belts,” Dr. Minkin adds.

//www.contitech.com" target="_blank" >www.contitech.com:www.contitech.com