Conveyor belts – lease, don’t buy

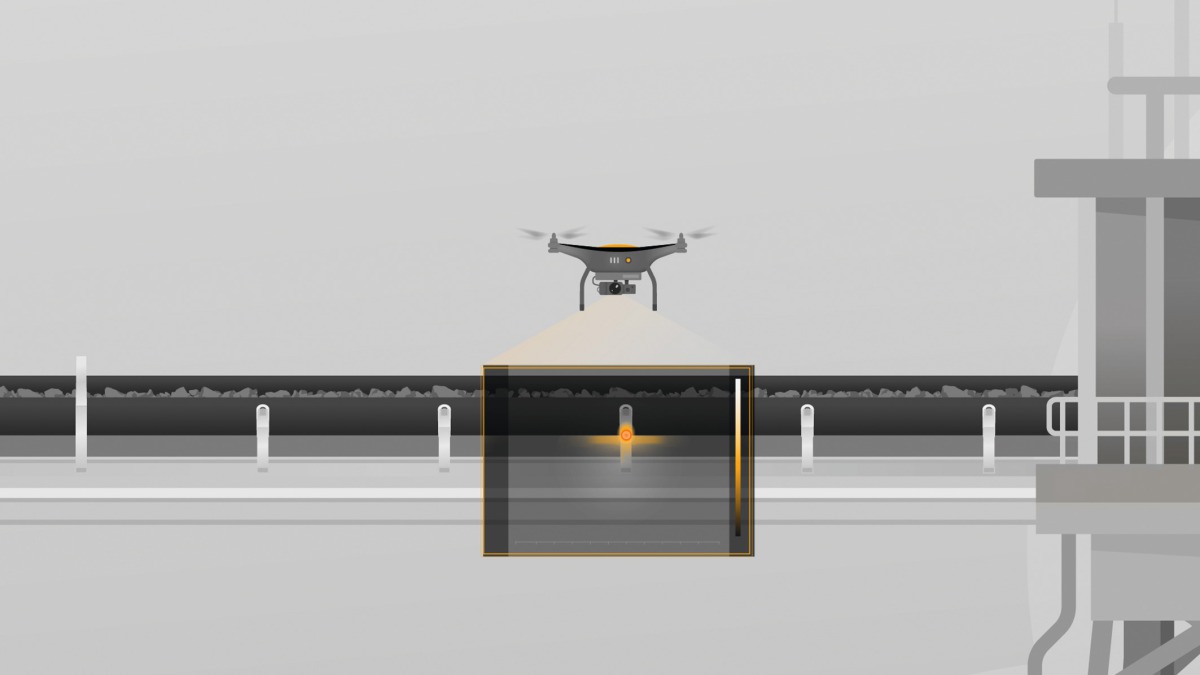

Continental is focusing more on the topic of service for conveyor belts used for all types of bulk and piece goods. Sensors monitor every movement of the conveyor belts and the materials conveyed. They inspect surfaces and report fill levels or incorrectly operating belts in real time. Databases store the information, and algorithms assess it and know when the belt needs to be serviced.

“Belt monitoring systems enable us to check the safety-relevant belt properties. At the same time, this technology provides the conditions for new business models such as pay-per-ton and predictive maintenance of components or systems,” says Jens Koster, who is responsible for business development, finance service and digitalization in the Conveyor Belt Group. Today, customers can already not just buy a belt, but also put together a complete package of conveyor belt and services. The customer benefits are obvious: outsourced system maintenance with simultaneously improved system availability.

The data monitoring requires extensive expertise in conveyor belts and specific knowledge of sensors, which Continental has within the corporation. All business units work closely together. This optimizes maintenance so that unplanned downtimes are a thing of the past. Continental uses both optical sensors and radar technology for this purpose.

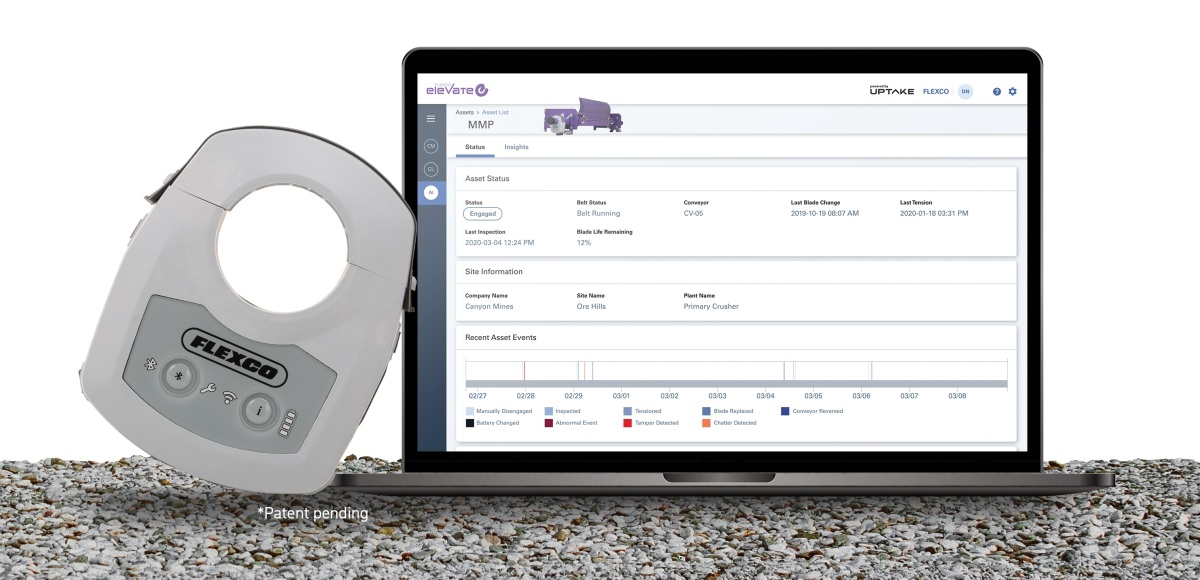

Online portal ContiPlus makes conveyor belt condition transparent

Part of the concept is the already-avail-able ContiPlus online service portal and an app for tablets and smartphones. Continental has created a digital solution that provides operators with important data about their systems at any time. More than 500 users – primarily in the United States, Canada, Mexico and Chile – already use the software to monitor around 1700 installed conveyor belts. The thickness of the cover plate, among other things, is determined at every service interval, using a mobile ultrasound device, and is stored in a database. This results in a complete picture of the condition. The program can then use the data to predict when a belt should be replaced because of wear. This means that the conveyor belt’s service life can be fully exploited – an important economic advantage. When the belt is coming to the end of its service life, the customer, distributor and sales employee receive a push notification on their mobile devices so that they can plan the belt’s replacement.

Monitoring systems detect damage early on

Due to the growing significance of digital technology in conveyor belt systems, Continental acquired South African company Advanced Imaging Technologies last year. It is known for its fundamental work on magnetics-based monitoring systems, which are used for the early detection of damage to steel cord conveyor belts. This allowed Continental to strengthen its expertise in the field of sensors and predictive maintenance. At the same time, the acquisition formed a strategic cornerstone in expanding the service offer for conveyor belt systems in industrial and mining applications. The technology developed by Advanced Imaging Technologies, for the international bulk goods solutions market, harnesses innovative magnet sensor technology. Thanks to additional connectivity, it enables continuous online condition monitoring of steel cord-reinforced conveyor belts. It also reduces the risk of belt failure by providing data that is used for timely planned maintenance work, thus reducing costly downtime. This technology provides a high-resolution, easy-to-interpret magnetic image of damaged or broken steel cords for the verification of potential alarm conditions. It makes it possible to monitor the splice integrity and the extent of the damage even over a longer period of time, enabling comparisons to be made with historic data. Customers benefit from innovative service offers that are based on data from the monitoring systems.

//www.contitech.de" target="_blank" >www.contitech.de:www.contitech.de

//www.continental-corporation.com" target="_blank" >www.continental-corporation.com:www.continental-corporation.com