Rohrdorfer is first cement plant in Germany to build CO2 separation plant

Germany’s first CO2 separation plant for cement production is currently being built on the premises of the Rohrdorf cement plant. The pilot project is a milestone for a climate-neutral cement production. Two tons of CO2 are captured per day and converted into raw material for the regional chemical industry.

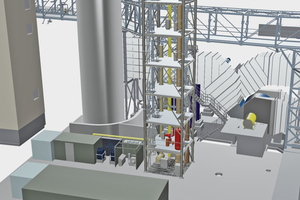

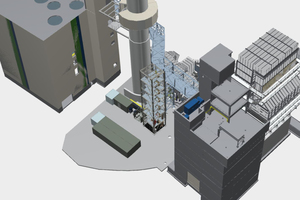

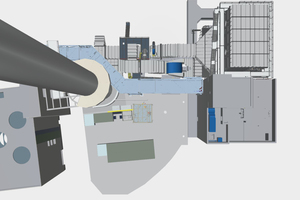

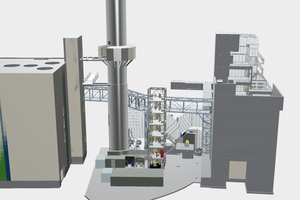

Rohrdorfer, the operator of the cement plant, is launching the pilot project on its own initiative in order to explore the possibilities of carbon dioxide capture and thus climate-friendly cement production. The plant, which is being built in cooperation with the Andritz Group, is scheduled to start up by the end of June 2022. It will capture 2 t of carbon dioxide per day, which will be put to further use in the regional chemical industry in the spirit of the circular economy. The total cost of the pilot plant is € 3 million and will be borne by Rohrdorfer.

The foundation for the plant on the south side of the Rohrdorfer cement works is already in place.The pilot plant will test the technical, qualitative and economic conditions for CO2 capture and conversion. Up to now, only empirical data from capture plants used in coal-fired power generation have been available.

Production of formic acid for the chemical industry starting in fall 2022

For the Rohrdorf cement plant, the Andritz Group has customized the plant so that, as a result, the optimum purity of the CO2 can be achieved while at the same time ensuring a high longevity of the chemical solvent used for separation.

Once the CO2 capture process has been sufficiently tested, Rohrdorf engineers and designers will expand the plant to produce formic acid, a versatile chemical, from the captured carbon dioxide. This is expected to be possible in the fall of 2022. Rohrdorfer has already been testing the extraction of formic acid from carbon dioxide in the company’s own laboratory since July 2021 in order to be optimally equipped for production in the pilot plant. Around 1800 l of formic acid can be obtained from the 2 t of CO2 captured per day in the plant. This is supplied to chemical plants in the region, for example, and serves as the basis for products such as cleaning agents, disinfectants or deicing agents. Depending on the degree of purity, the CO2 obtained can also be used in the food industry, for example for carbonic acid enrichment of mineral water.

CO2 as a carbon source important for the energy turnaround

The results of the pilot project are an important step for Rohrdorfer in achieving the German cement industry’s goal of producing climate-neutral cement by 2050. As early as 2022, cement will be produced at the Rohrdorf site with 45 % less CO2 than in 1990. This will be achieved by optimizing cement types and fuel use. By 2030, a reduction of 65 % is to be achieved. The remaining 35 % can only be reduced by capture. The pilot plant for CO2 capture is intended to accelerate this development.

Carbon dioxide capture is also an important contribution to the energy transition: Through the sector coupling of the chemical industry and the cement industry, the captured and converted carbon is to replace crude oil and natural gas in the chemical industry in the medium term. This is the start of a CO2 circular economy.

“We need to start seeing carbon dioxide as a valuable material instead of a problem material. The carbon in CO2 can become methanol, ethylene or formic acid, and thus a starting material for many products that today still have to be produced on the basis of petroleum. With this pilot project, Rohrdorfer is about to become a reliable partner for the chemical industry, for example at the chemical sites in Burghausen or Linz,” says Dr. Helmut Leibinger, Head of Plant and Process Engineering at Rohrdorfer. “With CO2 as a carbon source, Germany can protect the climate and at the same time become less dependent on oil and natural gas. In addition, value creation and thus jobs remain in the country.”

On 25 January 2022, Prof. Dr. Angelika Niebler, Member of the European Parliament and Deputy Party Chair of the CSU Bavaria, together with the Rohrdorfer management broke ground for the plant. Ms. Niebler welcomed Rohrdorfer’s initiative to proactively drive forward the production of CO2-neutral cement: “In order to achieve the goals agreed at the climate conference in Paris, determination and initiative are required. Rohrdorfer’s pilot project is outstanding and shows that German industry is ready to take responsibility.”