Shrinkage of eco-friendly concretes made with limestone-rich cements

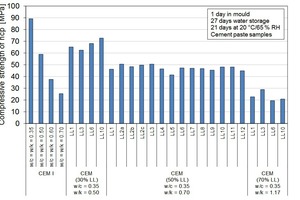

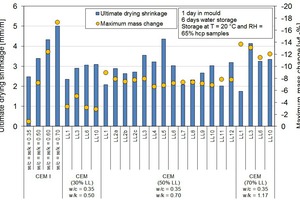

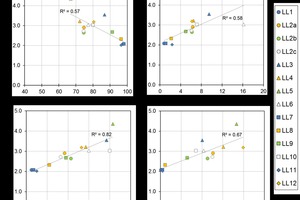

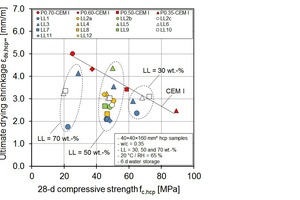

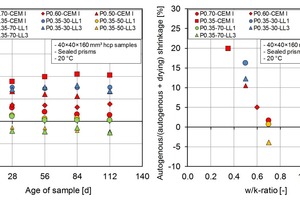

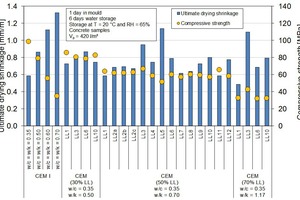

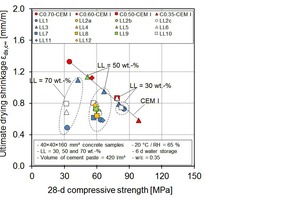

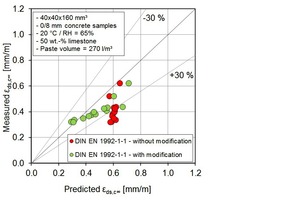

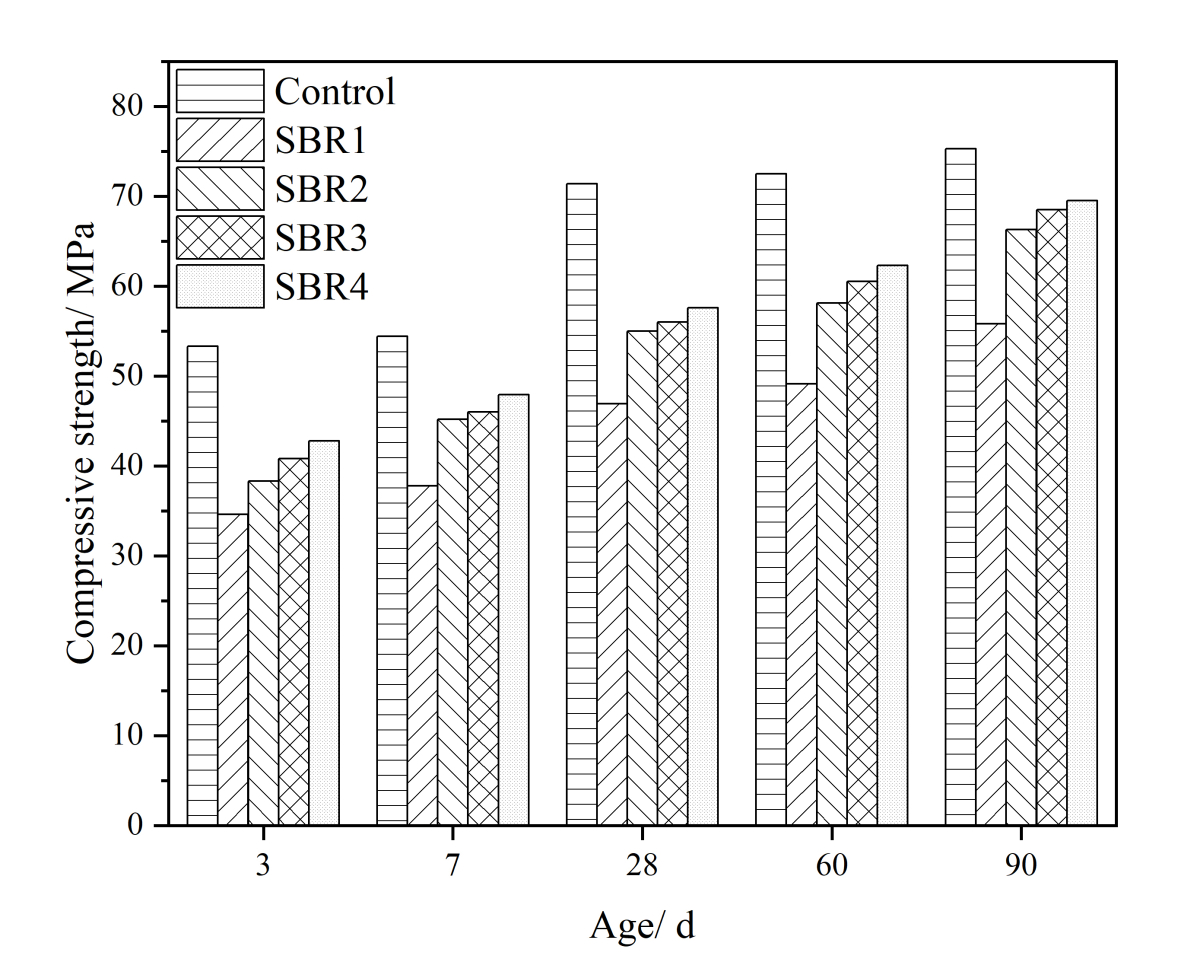

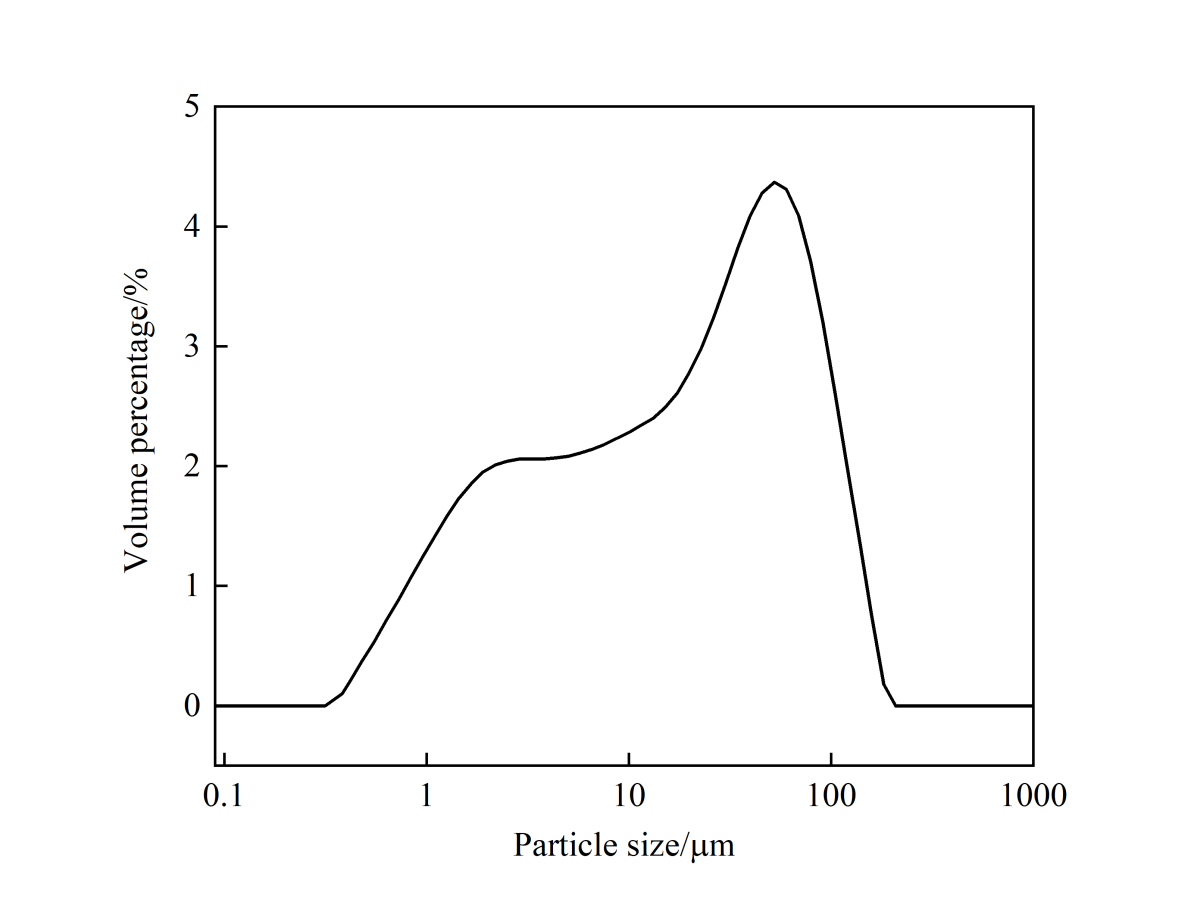

Excessive shrinkage deformation in concrete structures may lead to crack formation. Furthermore, in prestressed concrete elements shrinkage results in a significant loss of prestressing forces. Limestone-rich cements with limestone contents beyond the values of DIN EN 197-1 were developed in order to reduce the environmental impact of concrete. In this paper, the results of shrinkage behaviour of cement pastes and concretes made of limestone-rich cements up to 70 wt.-% are presented. Results revealed that the drying shrinkage of cement paste and concrete with high limestone contents strongly depends on the amount and the chemical-mineralogical properties of the limestone. In this context, methylene blue value (MB-value) and alkali oxide content of limestone were identified as the key parameters. Depending on the type of limestone, concrete samples made of limestone-rich cements had either higher or lower drying shrinkage than reference samples made of CEM I 52.5 R with the same w/c-ratio. However, lower drying shrinkage deformation was observed in comparison to the reference concrete made of CEM I with a comparable compressive strength.

1 Introduction

1.1 Problem definition and motivation

Concrete as the mass building material of the time is responsible for more than five percent of the global anthropogenic CO2 release [1]. The major environmental impact of concrete comes from the CO2 emissions during clinker production. It was realised that the reduction of Portland cement clinker in cement can lead to a decrease in the environmental impact of concrete. However, excessive substitution of clinker by limestone in Portland limestone cements (more than 35 wt.-%) with a common water/cement-ratio is reported to be critical [2]. To...