Research on the correlation between autogenous shrinkage and compressive strength of mortar modified by styrene-butadiene rubber

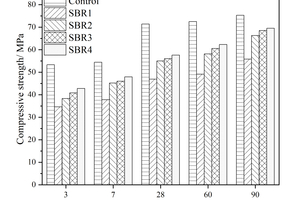

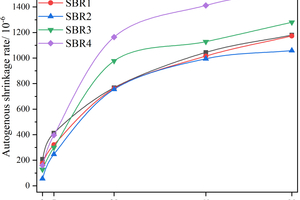

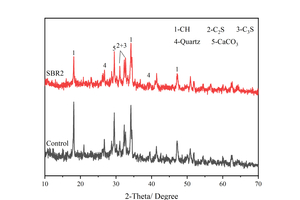

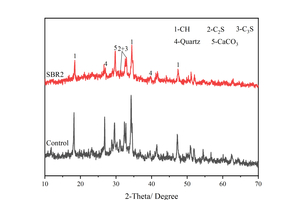

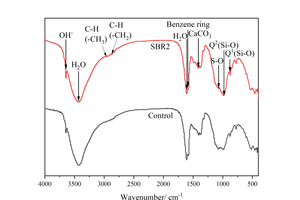

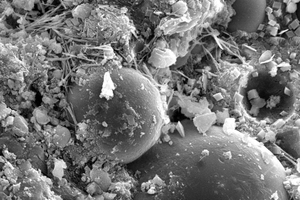

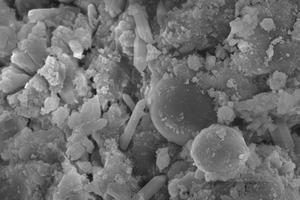

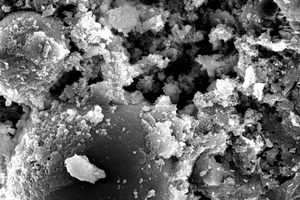

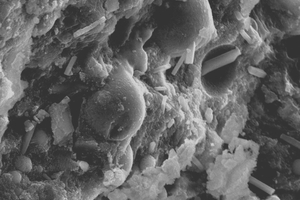

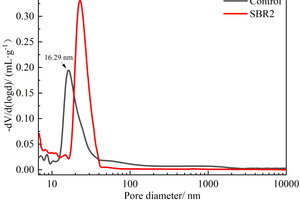

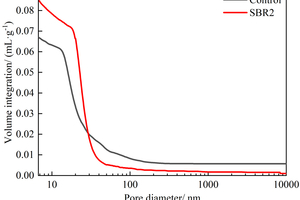

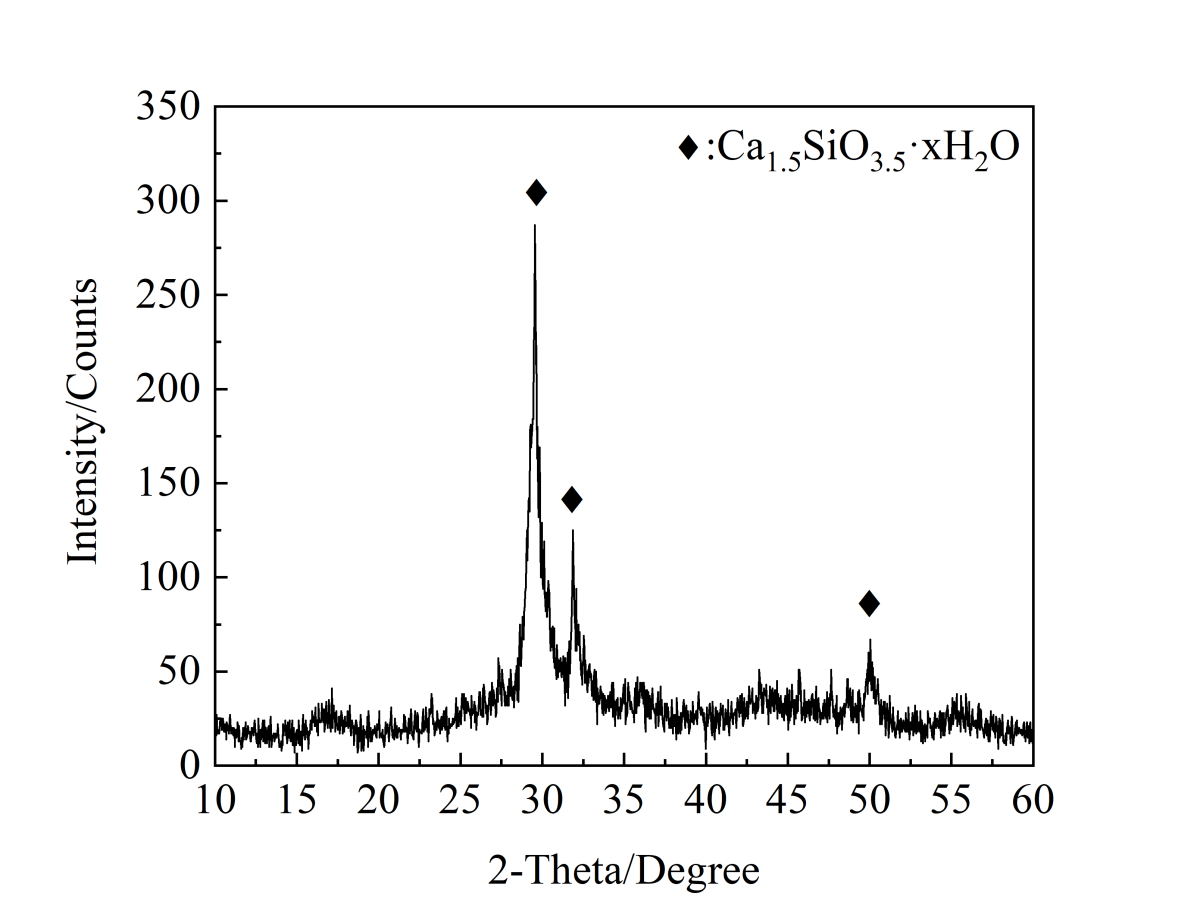

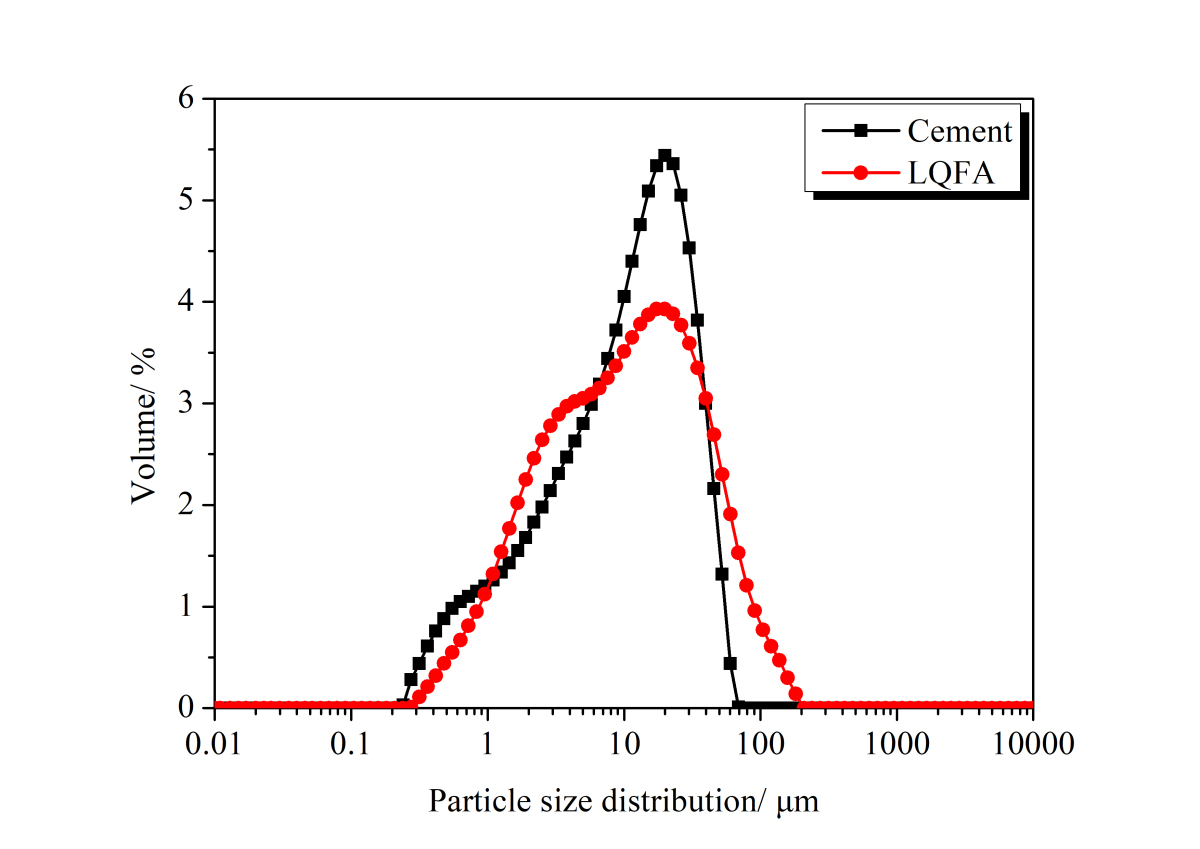

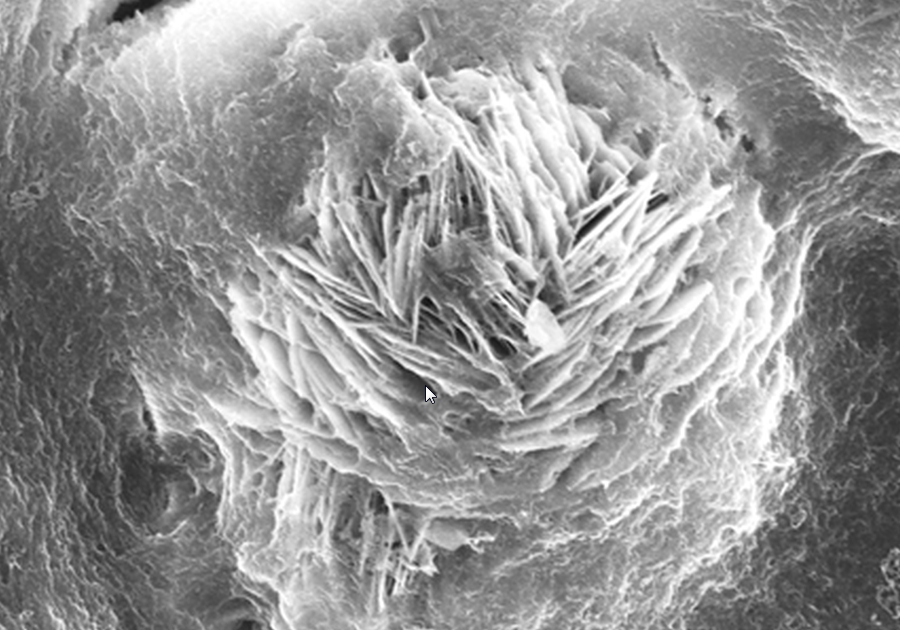

In this paper, the effects of styrene-butadiene rubber (SBR, 1%~4%) powder on the autogenous shrinkage and compressive strength of cement-based materials at 3, 7, 28, 60 and 90 d were firstly studied, then the mechanism behind was investigated by means of X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), scanning electron microscope (SEM) and mercury intrusion porosimetry (MIP), and at last the correlation between autogenous shrinkage and compressive strength was analyzed by establishing a mathematic model. Results show that the appropriate dosage of SBR reduces the dissolution rate of cement clinker, delays the arrival of the acceleration period, reduces the formation of hydration products, decreases the early hydration rate and inhibits the pozzolanic reaction between Ca(OH)2 and fly ash, thus reducing the autogenous shrinking and compressive strength of cement-based materials. In addition, there is a good linear correlation between autogenous shrinkage and compressive strength of SBR modified cement mortar, and such results can provide some reference for predicting autogenous shrinkage by compressive strength in practical engineering.

1. Introduction

Autogenous shrinkage is the self-deformation of cement-based materials independent of ambient temperature and humidity changes and external load conditions, and is the sum of self-drying shrinkage and chemical shrinkage [1]. In recent years, the strength requirement of engineering concrete has been increasing, and the water-cement ratio are constantly decreasing, resulting in a large number of cracks caused by autogenous shrinkage, which seriously affects the service life of concrete. In view of the problem of large autogenous shrinkage of high performance civil engineering...