System and method for aligning kiln shell sections

(22) 05.09.2017

(43) 08.03.2018

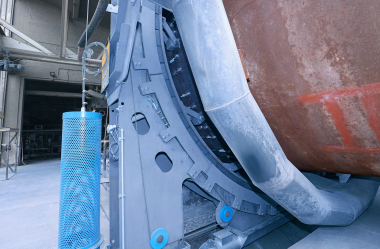

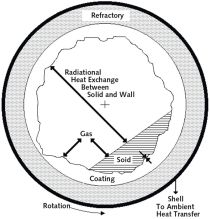

(57) A system for radially and axially aligning a new kiln shell section with an existing kiln shell section during a kiln shell section replacement or kiln erection process comprising: a tensioning device comprising a first alignment bracket on the new kiln shell section and a second alignment bracket on the existing kiln shell section, the alignment brackets being between stiffener braces on the kiln shell sections; a radial adjustment lug disposed on the first or second alignment brackets; and an axial stud connected to the first and second alignment brackets. Also provided is a method for radially and axially aligning a new kiln shell section with an existing kiln shell section during the kiln shell section replacement or kiln erection process.

(71) FLSmidth A/S, Vigerslev Alle 77, 2500 Valby (DK)

(84) ARIPO (BW, GH, GM, KE, LR, LS, MW, MZ, NA, RW, SD, SL, ST, SZ, TZ, UG, ZM, ZW), Eurasian (AM, AZ, BY, KG, KZ, RU, TJ, TM), European (AL, AT, BE, BG, CH, CY, CZ, DE, DK, EE, ES, FI, FR, GB, GR, HR, HU, IE, IS, IT, LT, LU, LV, MC, MK, MT, NL, NO, PL, PT, RO,RS, SE, SI, SK, SM, TR), OAPI (BF, BJ, CF, CG, CI, CM, GA, GN, GQ, GW, KM, ML, MR, NE, SN, TD, TG)