Technology improvement of production of sulfuric acid integrated with cement from phosphogypsum

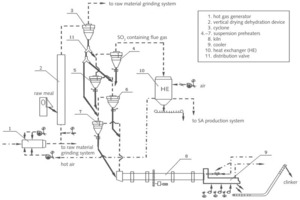

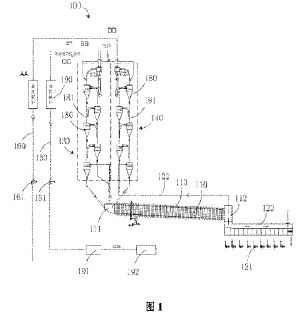

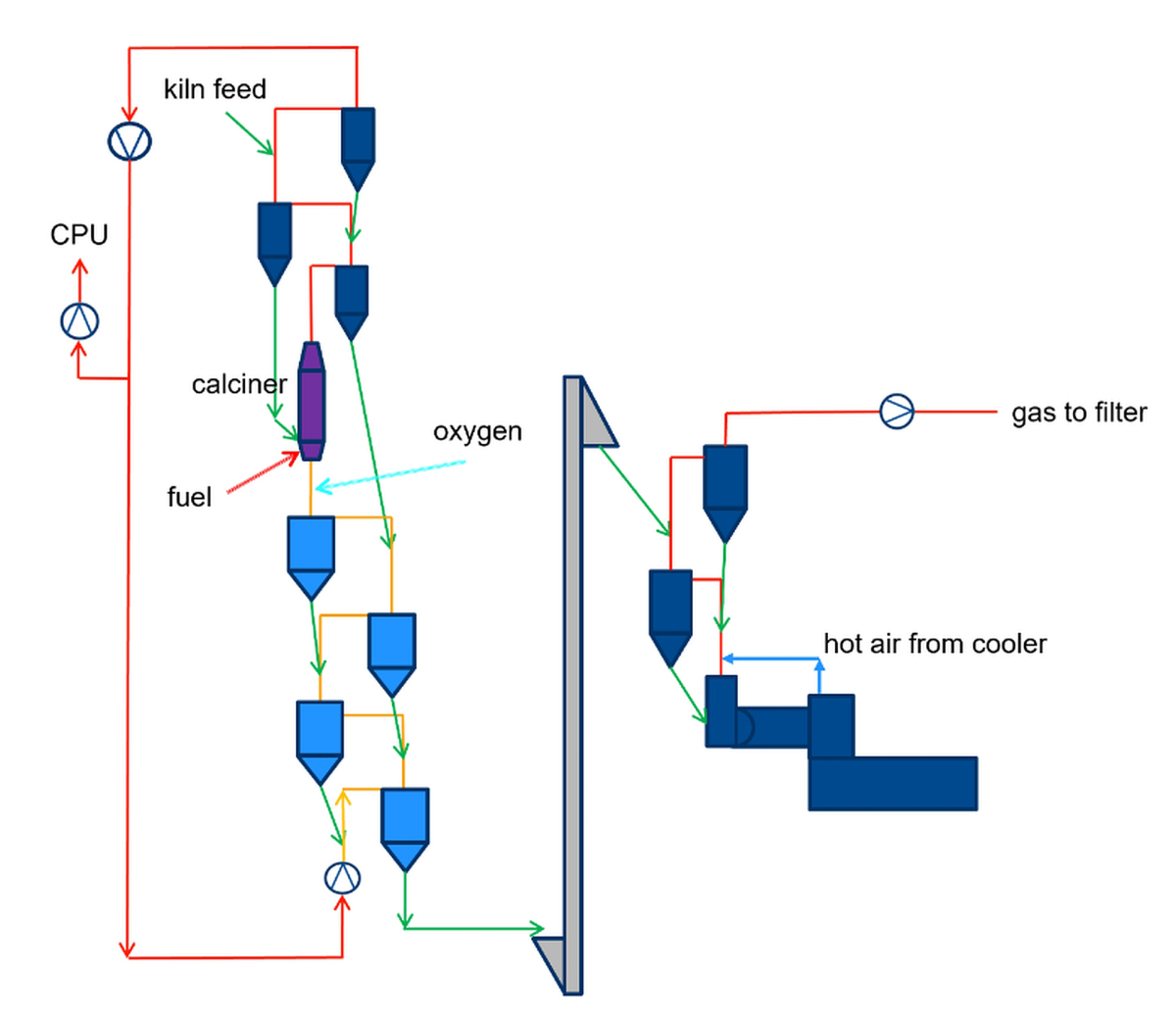

The improved drying and calcination process with a vertical drying dehydration device was proposed for the production of sulfuric acid integrated with cement from phosphogypsum, aiming at increasing the SO2 concentration in the flue gas and reducing the system heat consumption. The improved process has been applied in the design of a practical project in Ningxia (China) and is expected to be put into operation in 2016. The design of refractory materials for the pyroprocessing system was discussed. The feasibility analysis of the New Suspension Preheater (NSP) used in decomposition of gypsum has been carried out.

1 Introduction

Phosphogypsum is a kind of solid waste produced by wet-process phosphoric acid production, with annual emissions of more than 100 million tons worldwide and 50 million tons in China, respectively. The stacking of phosphogypsum leads to many problems such as taking up lots of land resources, polluting the air, water and soil, and increasing the high costs of construction and maintenance of the phosphogypsum stack. At present, about 10 % of the total phosphogypsum are used as a resource in China. For a long time, the utilization of phosphogypsum has been listed by the Chinese...