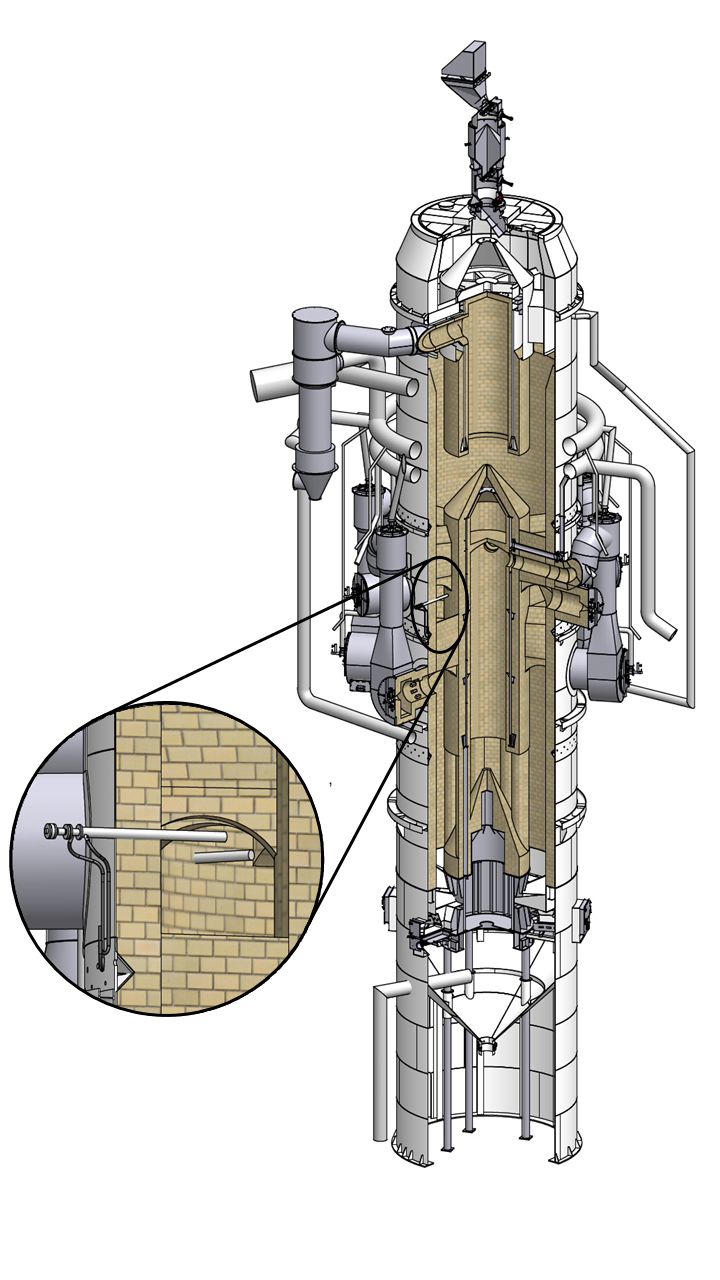

The reengineering of existing lime kilns

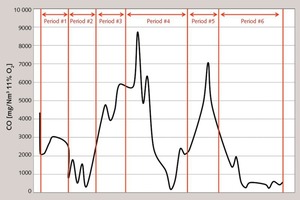

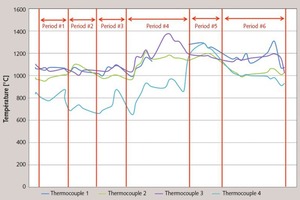

In developed countries, lime manufacturers become increasingly confronted with the challenge of producing lime in kilns that were designed decades ago when the constraints were different from nowadays. They are therefore required either to upgrade the existing installations or to invest in new equipment. As shown in a practical example, a cheaper alternative can consist of analysing thoroughly the existing process conditions so as to identify the minor improvements to be made in order to comply with the new markets or environmental requirements. In the presented, practical case, a lime manufacturer is operating two single shaft kilns. As the actual CO emissions are exceeding by far the future threshold, various tests and calculations were carried out to optimise the process conditions. As a result the CO emissions could be drastically reduced and the lime quality improved.

1 Introduction

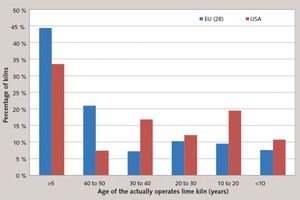

Based on different publicly available information sources (reference lists from lime manufacturers, public statistical reports, company reports, ...) the age of all lime kilns that are operated in the EU(28) and in the USA nowadays was estimated. These data enabled determination of the distribution of the kilns as a function of their age. The results are presented in Figure 1.

As can be seen from Figure 1, 65 % of the lime kilns in operation in the EU(28) are operated for more than 40 years. Although many new kilns were built in the USA in the last decades, there are still 40 % of...