The spice of gypsum

With approximately 11 billion m2 installed annually, gypsum boards are the most successful gypsum-based construction material [1]. The success of gypsum board is not only due to its excellent physical properties and functional advantages. It is also supported by an efficient, highly automated and continuous production line process which requires high quality raw materials. Besides gypsum binder, water and cardboard, a variety of chemical additives are used during today’s gypsum board production. An overview of the most relevant additives added to the gypsum core is provided based on the literature review and personal experiences. Special attention is given to the topics water reduction and setting time control.

1 Background

Gypsum boards are produced from gypsum plaster, water and additives for the gypsum core as well as cardboard on continuous conveyor lines.

Prior to diving into the chemistry of gypsum additives, a few basic principles of gypsum chemistry have to be recaptured. The chemical reaction of gypsum binder with water is a solution and precipitation process. The crystallization of gypsum follows the law of nucleation and crystal growth. The hydration of calcium sulphate hemihydrate to gypsum can be described with the equation

CaSO4 0.5 H2O + 1.5 H2O --> CaSO4 2 H2O (1)

Numerous partly desired...

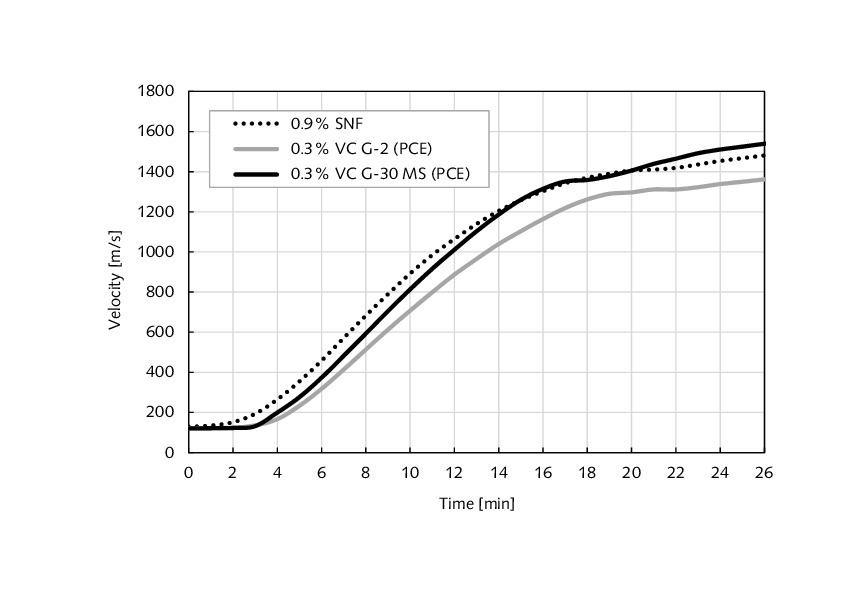

![4 Influence of the accelerator type on the plaster hydration [8]](/uploads/images/2017/w300_h200_x152_y136__305_273.-def2ae90c3533e23.jpg)