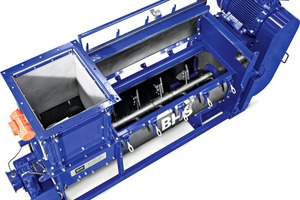

Twin mixing plant: Two different mixing procedures in one system

A new unparalleled mixing plant from BHS-Sonthofen has been in operation of late at Nikolaus Müller Kalkwerk-Natursteinwerke (Müllerkalk) in Üxheim-Ahütte in Rhineland-Palatinate close to the Belgian border: It combines the continuous moistening of agricultural lime and the batch production of mixed binders for ground stabilization measures. The new plant opens up new markets for Müllerkalk, thereby compensating for the somewhat seasonally fluctuating lime market. The fully automatic loading is a special feature: it is available approximately 24 hours a day, 7 days a week.

1 Introduction

Müllerkalk supplies both special binders for ground stabilization and agricultural lime from the Üxheim-Ahütte plant. The raw materials required for this mainly come from the lime works’ own quarries.

The company was founded in 1834 and has recently developed “Müllermix”, the new product for ground stabilization; it consists of a mixture of various lime products and Portland cement. It avoids several work steps in road construction, thereby cutting costs: “Müllermix” is milled into the ground and hydraulically bound – the ground no longer has to be excavated.

Apart from...